Chapter 4

Glass

Almost the total collection of glass from the Victoria excavations comprises the remains of so-called ‘black’ liquor bottles. In addition, some fragments of clear glass tumblers and broken wine glasses were recovered. In all, 96.6 kilograms of glass were recovered from the settlement.

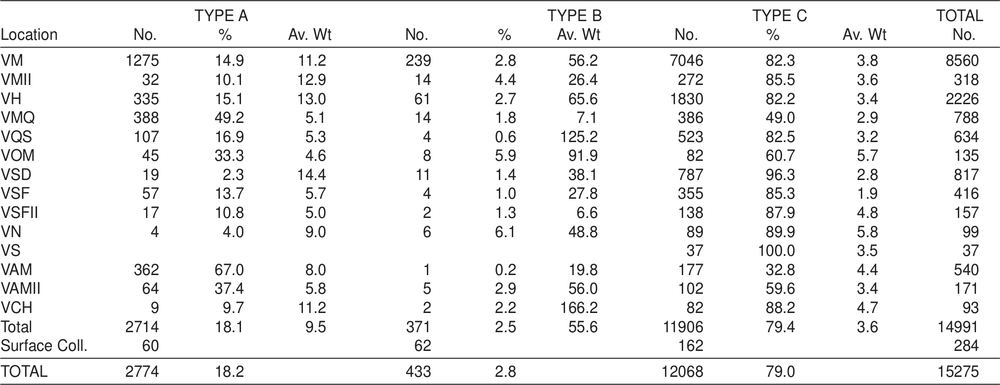

The glass was sorted initially into three categories, which are listed in each of the separate excavation reports. Type A includes all pieces thought to be possible Aboriginal artefacts, Type B includes all pieces of identifiable shape (bases, necks, rims et cetera) and Type C includes all pieces of unidentifiable glass. Following the analysis of category A, 206 fragments of bases were re-used in the analysis of category B. Table 74 shows the distribution of the total collection. The three areas of the hospital complex, VH, VHD, VHK, are included in the table as a single group.

The average weight of the samples in each unit (squares of surface collection and excavation) has been calculated. The largest collection, from VM, which constitutes more than half the total glass collection, was subjected to an analysis of variance according to weight (Bishop 1966:57-61). The analysis demonstrated a significant difference at the 1% probability level between the three categories, both of the surface collection and the excavated material. However, there was no significant difference between the surface and excavated material in any of the three categories.

Such a result appeared self-evident between Types B and C in terms of their initial selection, because those items readily identifiable by shape were almost always larger. However, the importance of this result is a) that there was little difference in the average weight between excavated and surface items in any category, suggesting that the breakage factor was similar whether the object was buried or exposed to natural agencies on the surface; and b) that there was a significant difference between Type A and each of the other two categories in both the surface and excavated material.

Type A items were heavier than Type C items but lighter than Type B items. In cultural terms this suggests deliberate selection of the raw material (the discarded bottles) by the Aborigines, who chose the heavier pieces of glass as being more suitable for modification as artefacts. In practice this usually meant a preference for the bases of bottles which were considerably thicker than the walls and necks. The process of modification normally resulted in these bases or ‘cores’ being broken, and these cores, the flakes detached from them and the retouched items that together comprise Type A, are consequently of less average weight than Type B.

TYPE A GLASS: THE ABORIGINAL ARTEFACTS

A total of 2,775 (18.2%) pieces of glass were isolated in the initial sorting as possible Aboriginal artefacts. In general, the assemblage is not a well defined one in terms of exact types which might be isolated in a comparable stone assemblage. This is probably because broken glass provides a larger number of random edges ready for use than stone. Thus, in this pre-selected group only 7.1% of the pieces bear definite secondary retouch.

As mentioned, Aborigines made special use of the heavy base portion of the bottle, and by examining the ways in which this raw material has been used the following classification of the glass artefacts has been established. Because of their broad nature it seems likely that these types may coincide with types as perceived by the original knappers, so that certain functional inferences can be drawn.

Because of the way in which these bottles were originally manufactured, the glass begins to thicken about two thirds of the way down the body wall. The bases in the Port Essington collection are formed predominantly with high conical omphaloi, that is, with much the same base shape as modern champagne bottles. In American glass terminology this is referred to as a ‘kick’. In the Port Essington bottles this base can be up to 30 mm thick, providing a solid block of glass not unlike obsidian. The process appears to have been to flake the thickened part of the wall, downwards to the base, detaching flakes with similar attributes to stone flakes – a bulb of percussion, stress lines et cetera. Thus the base can be regarded as a core, which if broken in half, can also be flaked on the kick; it can also be utilised as a tool.

Table 74. Total collection of glass from Victoria, by type, percentage and average weight in grams.

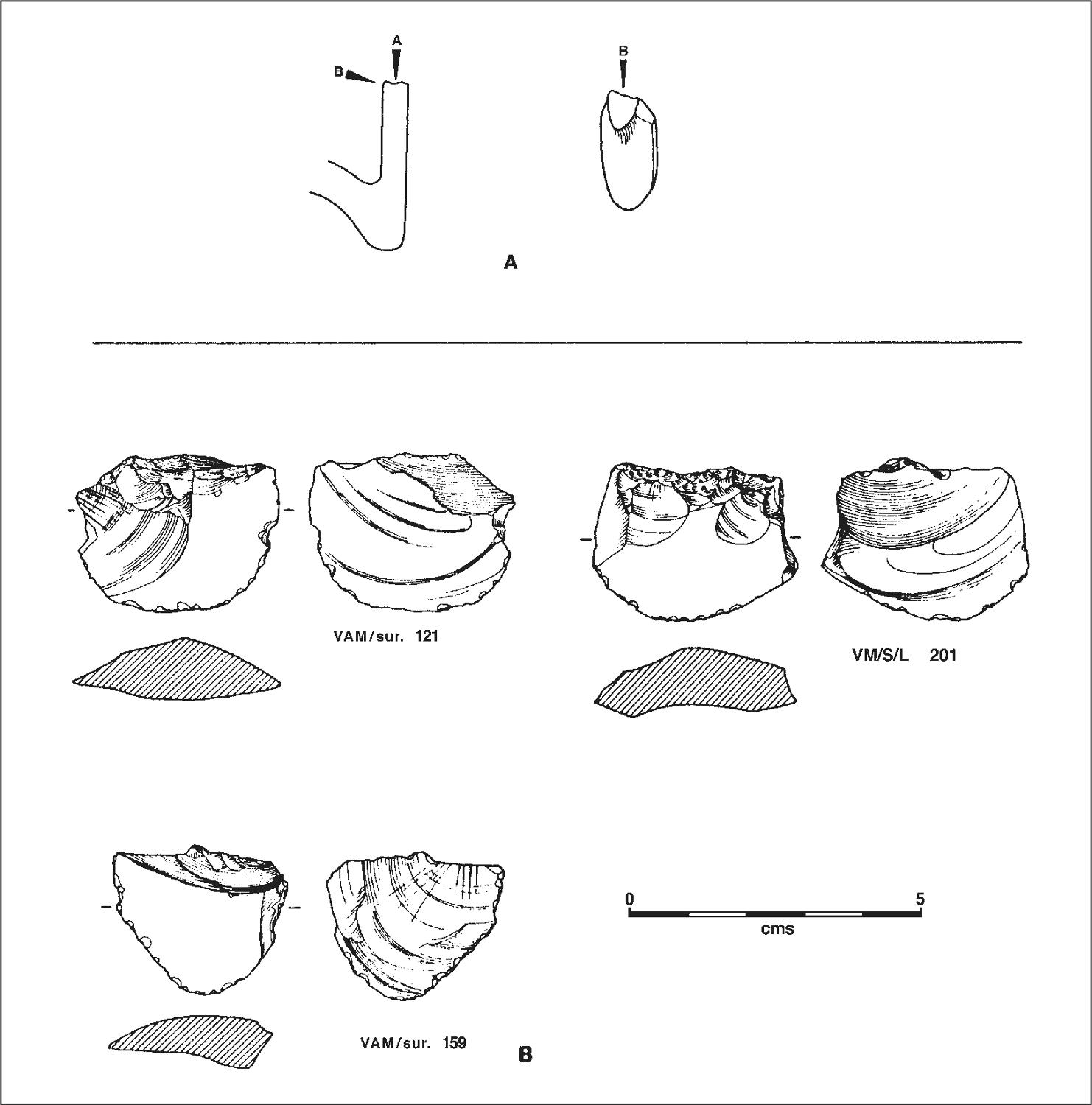

80Two methods of flaking the wall of the bottle appear to have been used in this collection. If the blow is directed at the broken edge of the glass, that is, the broken edge is used as the striking platform, the detached flake assumes the form of an ordinary stone flake. However, if the inside surface of the bottle wall is struck, a complete semicircular section of the inside wall detaches so that a flange of glass is produced on the outer wall of the detached flake, whose circumference is greater than the inside wall section. I was able to replicate both sorts of flakes experimentally using simple direct percussion with a hammer stone.

Figure 81. a) Glass flake production techniques. Both the top of the wall and the inside of the wall might be used as a striking platform. In the latter case part of the interior surface might be retained. b) Numbers 121 and 201 retain part of the interior surface, while 159 does not.

Figures 81a and 81b illustrate these two types. Both sorts of flake were produced at Port Essington, and they are treated as a single group in the present analysis, with the presence of the internal face being taken as the equivalent of the bulb of percussion. The important point is that both flakes produce a sharp cutting edge without the necessity of retouch. Base cores and flakes form the two common types of glass implements found at Port Essington. The retouched implements are mainly scrapers, although some ‘cutting flakes’ bear secondary retouch as well as usewear. An additional category of ‘utilised pieces’ is included where usewear occurs on pieces of glass which do not exhibit the characteristics of flakes – bulbs or percussion and so on. In this secondary analysis a large percentage of pieces originally included in Type A have been excluded and are treated as waste flakes. These are pieces which either have a bulb of percussion but lack usewear, or pieces on which the usewear flaking was probably produced by non-human agencies. The percentage type distribution is shown in Table 75.

Table 75. Glass Type A: percentage distribution of Type A glass according to artefact classification.

| Location | Number | Base Cores | Flakes | Retouched | Utilised Pieces | Waste Flakes |

| VM | 1275 | 7.0 | 9.4 | 8.7 | 22.6 | 52.3 |

| VAII | 32 | 6.3 | 3.1 | 15.6 | 50.0 | 25.0 |

| VH | 335 | 9.9 | 12.5 | 5.4 | 29.3 | 43.0 |

| VMQ | 388 | 4.1 | 17.0 | 2.1 | 16.8 | 60.1 |

| VQS | 107 | 1.9 | 16.8 | 7.5 | 23.4 | 50.5 |

| VOM | 45 | 4.4 | 26.7 | 4.4 | 11.1 | 53.3 |

| VSD | 19 | 10.5 | 15.8 | 10.5 | 42.1 | 21.1 |

| VSF | 57 | 8.8 | 7.0 | 5.3 | 15.8 | 63.2 |

| VSFII | 17 | 17.7 | 11.8 | 70.6 | ||

| VB | 4 | 25.0 | 25.0 | 50.0 | ||

| VAM | 362 | 8.0 | 16.9 | 8.6 | 21.8 | 44.8 |

| VAMII | 64 | 4.7 | 12.5 | 3.1 | 26.6 | 53.1 |

| VCH | 9 | 22.2 | 11.1 | 33.3 | 33.3 | |

| Surface Collection | 60 | 33.3 | 20.0 | 8.3 | 28.3 | 10.0 |

| TOTAL | 2774 | 7.4 | 12.7 | 7.1 | 22.8 | 50.1 |

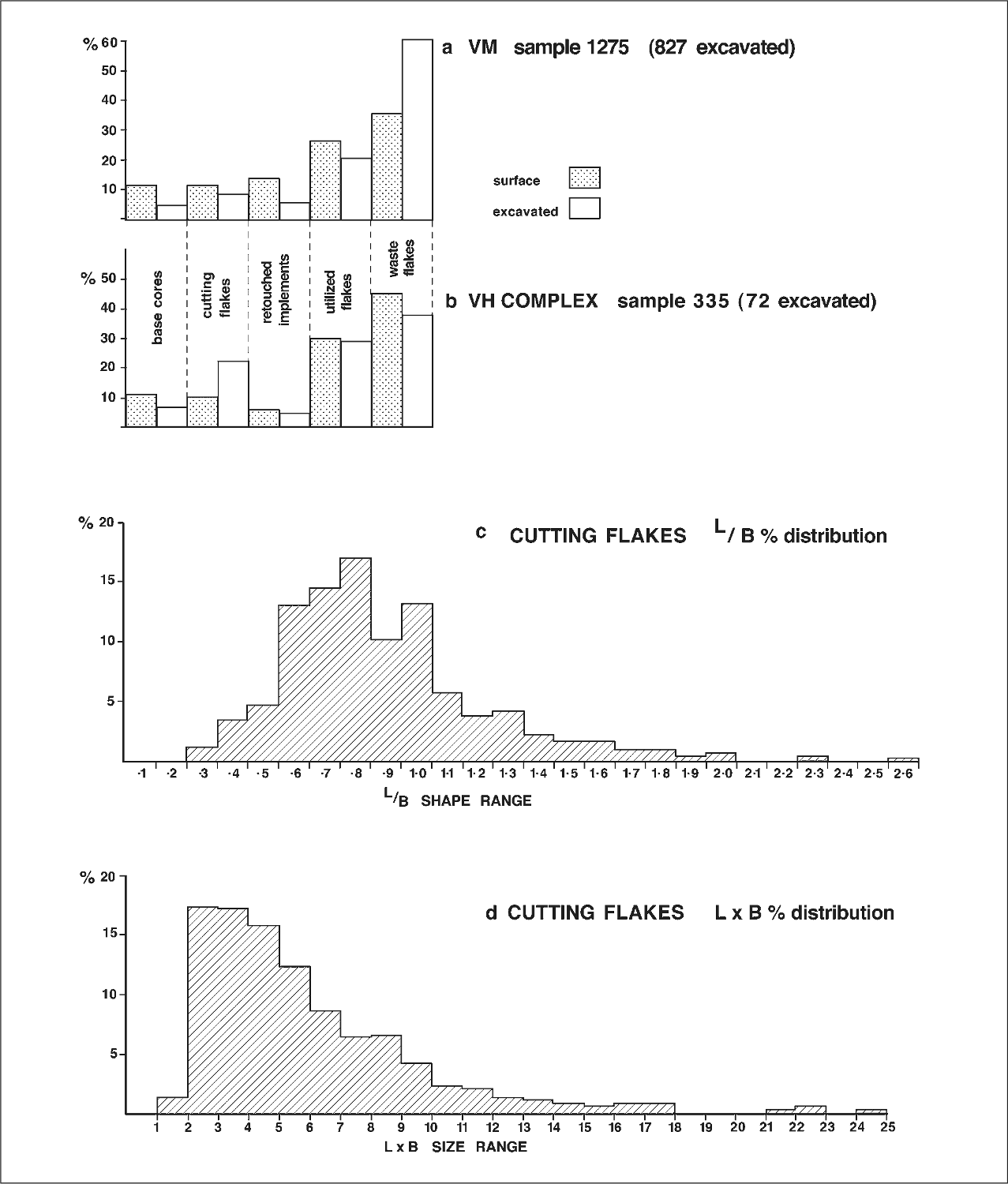

In this table the surface and excavated materials have been added together. Figures 82a and 82b give two histograms, showing the relationship between the excavated and surface material for the two areas in which large quantities of glass were present on the surface. In the case of VM a definite pattern is discernible. The excavated material contains a far greater number of waste flakes and consistently fewer base cores and implements than the surface material. A reasonable explanation is that during the British occupation, VM provided an area of raw material for the manufacture of 81artefacts and useful cores that were taken elsewhere. Subsequent to the British abandonment, VM was occupied by the Aborigines in a more general and perhaps spasmodic fashion.

The histogram of the VH complex shows no such clear trend. One reason may be that the excavated sample is too small, but it seems more likely that there is no significant difference between the surface and excavated materials. The other areas have much less surface material, and histograms calculated for these areas show no significant difference between the surface and excavated glass.

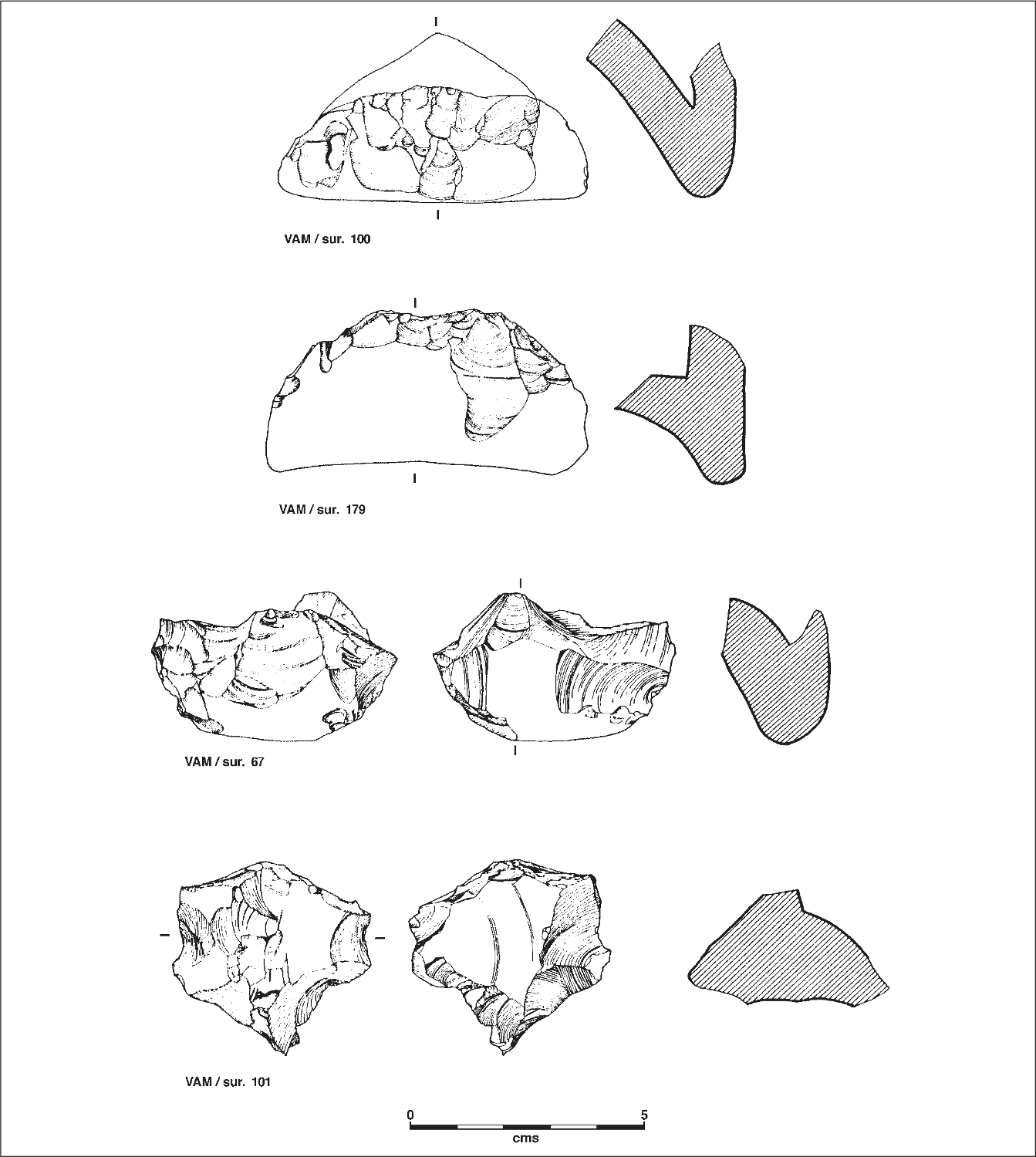

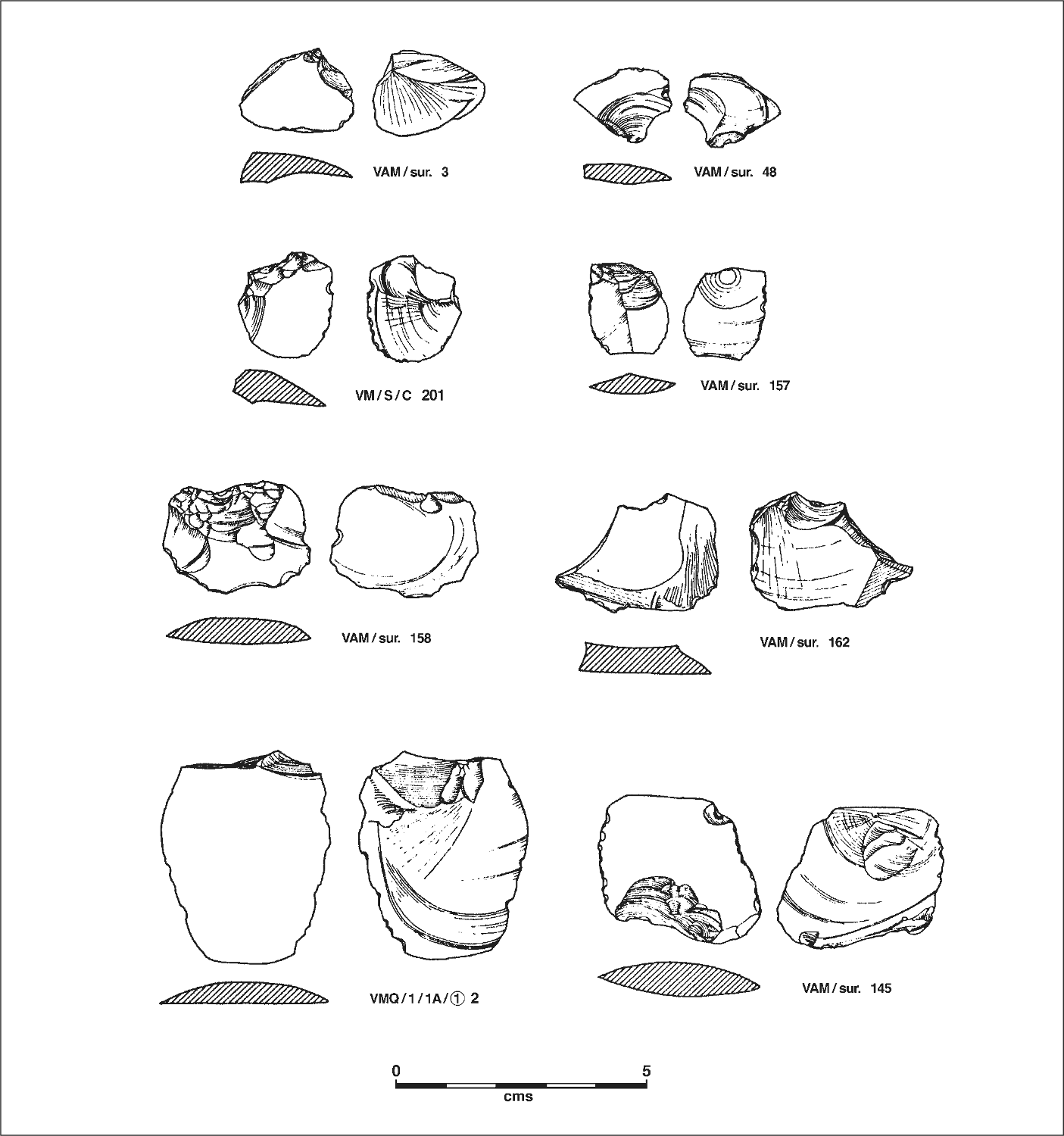

Base Cores (Figure 83)

Two hundred and six items (7.4% of Type A glass) were classified as cores. As stated, all the cores in this collection are bases of bottles. A number of metrical calculations were made on these base cores in order to describe them more fully and to delineate the modifications made on them by the Aborigines.

Figure 82. a and b) Distribution of glass artefact types in the excavated and surface material for VM and the hospital complex. c and d) Shape and size distributions for cutting flakes in the collection. 82

Figure 83. Bottle bases used as cores and recovered from the Aboriginal midden VAM.

Percentage of remaining base

Of the 206 items with flakes removed from the wall, only four were whole bases. On the other hand, of the collection of bases with no flakes removed, more than 60% were whole. Two reasons may explain why this breakage was deliberate rather than completely fortuitous, or even a probable by-product of flaking the walls. Firstly the kick could then be flaked, and because of its convenient curved shape also used as a tool; and secondly, the flaked wall became a convenient scraper that would have been less efficient if the base were whole.

Five ranges of the percentage of remaining base were set up and the collection was sorted into these groups (Table 76).

Table 76. Glass Type A: percentages of base remaining.

| Percentage of remaining base | <25 | 25–49 | 50–74 | 75–99 | 100 |

| 70.9% | 24.8% | 2.4% | 0% | 1.9% |

This distribution emphasises the non-random nature of the use of this raw material. Once it was determined that a base was suitable as a core it was mostly worked until it was spent and obtaining new useful flakes had become difficult or impossible. 83

Wall Height

The maximum height of the remaining wall above base was measured for each item and correlated with the percentage of remaining base. If the collection was fortuitous no correlation could be expected. However if the bases had been deliberately flaked, the wall height should be smaller where less of the base remained, and greater where more of the base remained (Table 77).

Table 77. Glass Type A: relationship of wall height (mm) to percentage of remaining base.

| Percentage of Remaining Base | <25 | 25-49 | 50-74 | 75-99 | 100 |

| Sample (No.) | 146 | 51 | 4 | 0 | 5 |

| Average Maximum Wall | 27.5 | 32.5 | 40.0 | 50.3 | |

| Height Standard Deviation | 7 | 9 | 7 | 19 |

While this result is not conclusive, since sample sizes are disproportionate and the range of each category overlaps the next, the progression is still evident. It suggests that a real correlation exists, which relates to the deliberate utilisation of the glass as a raw material and supports the observations made in the previous test of the percentage of remaining base.

Flaking

The most general methods of flaking the walls of bottles have been described above. However a more detailed analysis of the base cores showed that unifacial flaking in both directions (the inside and outside of the bottle wall acting as the dorsal surface) occurs as well as bifacial flaking. Flaking in this context refers only to primary flaking, although some secondary flaking may occur. Deliberate secondary retouch is difficult to identify on this material, and secondary retouch has been included as an aspect of usewear dealt with below. On average, the flake scars on these base cores are roughly 5 mm by 5 mm, or larger. The use of the internal wall as the striking platform is the most common technique, and here the flake scars appear on the outer surface. This has been labelled external unifacial flaking. The opposite process producing flake scars on the inner surface has been labelled internal unifacial flaking. Table 78 gives the percentage occurrences for these flaking techniques.

Table 78. Glass Type A: percentage distribution of flaking styles on base cores.

| External Unifacial | Internal Unifacial | Bifacial |

| 75.2 | 21.9 | 2.9 |

Percentage of flaked wall

A large majority of the collection is completely flaked around the wall which remains. A set of ranges was set up and Table 79 gives the percentage of the collection within each range. This figure is obviously independent of the amount of wall remaining.

Table 79. Glass Type A: the percentage distribution of the Type A bases according to the amount of edge bearing negative flake scars.

| Percentage Range of Remaining Edge that is Flaked | >25 | 25–49 | 50–74 | 75–99 | 100 |

| Occurrence | 1.47 | 7.28 | 8.25 | 2.43 | 80.58 |

It was noted that none of the five examples where 100% of the base remained was flaked along more than 50% of the edge. Again the overall result of this test reflects the systematic reduction of bases deemed suitable as cores.

Presence of flaking on kick

On a number of items the amount of remaining kick was so small as to be virtually absent. While on these examples flaking was regarded as not present, for the total collection 48.5% of the kicks had been flaked.

Usewear

Two common forms of usewear were noted. Bruising of the glass (small internal cracking) occurred along the flaked edges and sometimes the bases, while in many cases, small unifacial and bifacial flakes had been removed from the primary flaked edges. Similar flakes were occasionally detached from unworked edges of the kick, particularly where the natural curve of the glass would facilitate its use for scraping purposes. The percentage occurrences for usewear on the walls and kicks were calculated Table 80.

Table 80. Glass Type A: percentage occurrence of usewear on walls and kicks of base cores.

| Usewear on wall | Usewear on kick | |

| Occurrence | 68.9 | 64.1 |

The VM Sample

Following the trends noted for the surface and excavated material from VM for the total Type A glass range (Figures 82a and 82b), the respective figures for VM surface and VM excavated base cores were tabulated in Table 81. In addition the comparative figures for the Aboriginal midden, VAM, and the total collection are given.

Table 81. Glass Type A: comparisons of base cores from VM with VAM and the total collection by percentage. See text for details.

| VM excavated | VM surface | VAM | TOTAL COLLECTION | |

| Number of Items | 37 | 52 | 29 | 2774 |

| Base Remaining (%) | ||||

| <25 | 54.1 | 71.2 | 75.9 | 70.9 |

| 25-49 | 35.2 | 28.9 | 20.7 | 24.8 |

| 50-74 | 2.7 | 3.5 | 2.4 | |

| 75-99 | ||||

| 100 | 8.1 | 1.9 | ||

| Flaked Wall (%) | ||||

| <25 | 2.7 | 1.9 | 3.5 | 1.5 |

| 25-49 | 16.2 | 3.9 | 3.5 | 7.3 |

| 50-74 | 13.5 | 9.6 | 10.3 | 8.2 |

| 75-99 | 2.7 | 3.9 | 2.4 | |

| 100 | 64.9 | 80.8 | 82.8 | 80.6 |

| Flaking Technique (%) | ||||

| External Unifacial | 64.9 | 78.8 | 72.4 | 75.2 |

| Bifacial | 35.1 | 19.2 | 24.1 | 21.8 |

| Internal Unifacial | 1.9 | 3.5 | 2.9 | |

| Flaked Kick | 35.1 | 69.2 | 48.3 | 48.5 |

| Usewear (%) | ||||

| On wall | 64.9 | 82.7 | 86.2 | 68.9 |

| On kick | 62.2 | 69.2 | 93.1 | 64.1 |

The technique of bifacial flaking in the excavated VM sample is proportionally higher than in the surface collection, 84suggesting that it became less important through time. However the important trend, which is consistent throughout the other metrical analyses, is the less intense exploitation made of the VM excavated material. Only 54.1% of this sample of base cores has less than 25% of the base remaining, compared with over 70% for the VM surface material, the VAM material, and the total collection. Again only 64.9% of this collection has the total wall flaked, compared to 80+% in each of the other three groups; only 35.1% of the kicks are flaked, compared with 69.2% of the VM surface collection, and 48% of the other two groups. There is also slightly less usewear on the base cores from the VM excavated sample.

These results are consistent with the results of the histogram. During British occupation VM provided a source of raw material, when it was equivalent to a normal Aboriginal quarry site. After the British abandonment, Aboriginal occupation could become more general, while the cessation of supplies of raw material occasioned more intense usage of what remained.

Cutting Flakes (Figures 81 and 84)

Three hundred and fifty struck flakes from the Type A collection bore traces of utilisation on the sharp cutting edge. In each case this usewear continued along the edge for more than 50% of its length, and in the majority of cases for almost 100%.

The most common form of usewear found on these flakes is what Schrire (White 1967:47) termed ‘snap-break’ usewear where an elliptical flake is snapped off the thin edge so that a square profile is left on that edge. In addition, minute, irregular unifacial and bifacial flaking does occur.

Figure 84. Cutting flakes from Port Essington.

85It is extremely difficult to demonstrate that such flaking could not have occurred naturally, and therefore no detailed analysis of usewear was carried out. What seemed important during the analysis was that such usewear did not occur on all struck flakes, being absent particularly on the smaller flakes. In order to test this observation the VM excavated material was chosen as a sample. From the 504 items designated waste flakes, those with bulbs of percussion present (i.e. those that could certainly be regarded as struck flakes) were isolated. This group numbered 148 items (29.4% of the waste flakes). Weight was chosen as an indication of size and the average weight of this group was 1.7 gm. Of the VM excavated material sorted as utilised cutting flakes the average weight per item was 4.2 gm. Thus the struck flakes with utilisation are on average significantly heavier than the struck flakes without utilisation.

Figure 85. Scrapers made on bases. While scrapers are the most ambiguous artefacts to identify (see text for discussion) three of these four pieces came from the Aboriginal midden VAM.

On the basis of this observation two metrical calculations were made in order to indicate the shape and size ranges of these cutting flakes. Two measurements were taken on each flake: length, being the maximum length of the flake at right angles to the striking platform, and breadth, being the maximum breadth at right angles to the length measurement. By dividing length by breadth a shape range was obtained. For example, 0.5 indicates that the length is equal to twice the breadth; 1.0 indicates that length equals breadth; 2.0 indicates that the length is equal to half the breadth. Figure 82c shows the percentage distribution of the cutting flakes according to shape. From this histogram it will be seen that 68.9% of the collection falls into the range of 0.5 to 1.0; that is, the majority of the collection falls into the category of ‘side-struck’ flakes, which ranges from flakes which are twice as broad as they are long, to flakes which are approximately square. Also of interest are the few examples of flakes which are much longer than they are broad (see discussion below). In general, however, the shape range is seen as reasonably limited.

By multiplying the length and breadth measurements, a size range was obtained; Figure 81d gives the percentage distribution. Eighty four percent of the collection falls within the range 3–9 sq cm and 50.2% of the collection is within the range 3–5 sq cm. Again the collection contains a few large struck flakes, but the majority of the cutting flakes fall within a limited range. The significance of size is discussed below.

A common aspect of these cutting flakes was the presence of primary flake scars. These were noted on 87.7% of the flakes and they occurred always on the dorsal surface of the flake, in the region of the striking platform. Thus they represent flakes taken from higher up the bottle wall, as it was worked towards the base.

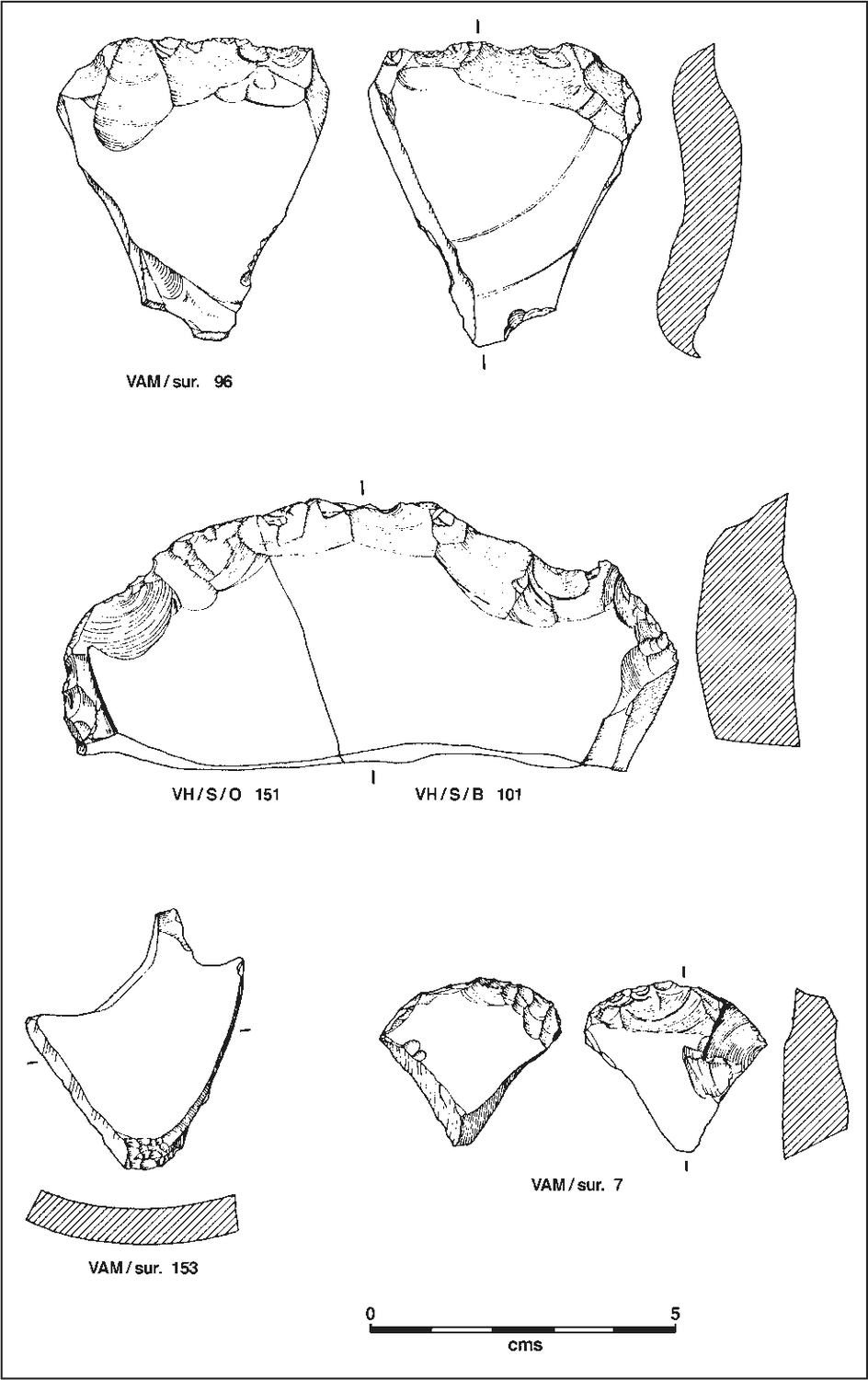

Retouched Implements (Figure 85)

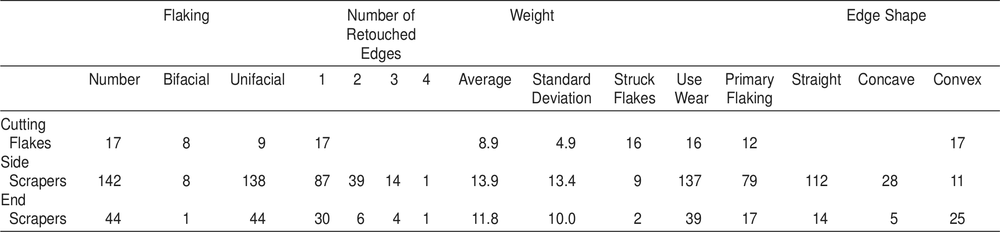

A total of 196 items appeared to have been deliberately retouched for use as implements (Table 82). Of these 17 (8.7%) were cutting flakes which differed from the category of cutting flakes described above only in that they appeared to be deliberately retouched. All the remaining items fell into the generic category ‘scraper’. Very few of these had been made on struck flakes, and could be sorted on morphological grounds into ‘side’ and ‘end’ scrapers, but the division is perhaps more apparent than real. The ‘side’ variety occurs on 142 examples, while the ‘end’ variety occurs less frequently on 44 examples. Occasionally both occur on a single item. This explains the discrepancy in numbers in Table 82.

Each of these categories was analysed in respect to manner of flaking, presence of usewear and primary flaking, weight, and presence of percussion bulb. In addition, the number of retouched edges on the scrapers and the general shape of these edges were recorded.

Table 82. Glass Type A: analysis of retouched implements. Weight in grams. Total artefact numbers here exceed 196 artefacts because side and end scrapers can occur together on a single item.

86

Retouched cutting flakes

In shape and size these cutting flakes fall within the range of the utilised cutting flakes described above. However most are at the large end of the scale. Of the 17 items with retouched edges, 8 are retouched bifacially, 9 are retouched unifacially, 16 items have a definite bulb of percussion; 16 bear traces of usewear, again predominantly ‘snap-break’ fracture; and 12 items have primary flaking on the dorsal surface about the striking platform. The average weight of these items is 8.9 gm, with a standard deviation of 4.9.

Side Scrapers

Despite the apparent presence of deliberate retouch on these scrapers, their authenticity as Aboriginal artefacts is difficult to verify. Random pieces of glass were used, and although the average weight for the 142 classified items is 13.9 gm, the standard deviation for the collection is 13.4. (The weight range extends from 1.1 gm to a single item weighing 109.3 gm.) Nevertheless the average weight indicates that heavy pieces were selected. Flaking is common on more than one edge, and 211 flaked edges are represented on the 142 items (Table 83).

Table 83. Glass Type A: number of side scrapers according to number of flaked edges present.

| No. of flaked edges | 1 | 2 | 3 | 4 | Total |

| No. of items | 87 | 39 | 14 | 1 | 142 |

Nine scrapers are made on struck flakes.

Flaking is predominantly unifacial, occurring on 138 items, while bifacial flaking occurs on only eight items (four have evidence of both). The flaked edges are predominantly straight, this occurring on 112 items, while convex edges occur on 11, and concave edges on 19 items.

Perhaps the most convincing aspect of these scrapers is that primary flaking occurs on 79 items and usewear is present on 137 items.

End scrapers

In general, the reservations held for the side scrapers are also true for the end scrapers. While there is an average weight of 11.8 gm for this category, the standard deviation of 10.0 is still large. Only two struck flakes have been used, and bifacial flaking occurs only once. Unifacial flaking occurs on all 44 items. Again, however, there are 56 flaked edges on the 44 items, and usewear occurs on 39 items, while primary flaking occurs on 17 items. Also of interest is that on these end scrapers the edge is convex on 25 items, concave on 5 items and straight on only 14 items.

A summary of the retouched implements is contained in Table 82.

Utilised Flakes

Six hundred and thirty one items in the collection were classified as utilised flakes. These are most usually random pieces of glass which have had various sharp edges utilised, presumably for cutting. Again there is little form in the pieces utilised, which range in weight from 1.0 gm to 96.1 gm. However the average weight is again high, 14.1 gm, with a standard deviation of 9.7, again suggesting that the tendency is towards the heavier pieces of glass. The usewear is the same as that described for the cutting flakes, which really form a specialised group within this category.

Waste Flakes

Upon re-examination in the laboratory the remainder of the glass initially sorted as Type A was placed in the category of waste flakes. These represent struck flakes that have no usewear, or pieces on which the flaking and/or usewear is random and therefore dubious. This group numbers 1382 items. It is of interest that amongst the 233 items in this category from VMQ, 167 (71.6%) are in fact struck flakes without usewear. This is the highest percentage for any area and accords well with the interpretation of this area representing a flaking floor. From the other areas, the percentage is normally about 20% for struck flakes in this category.

Also of interest is that the average weight of the waste flakes, 2.9 gm, is considerably lower than all other categories of Type A glass, confirming the general impression gained throughout the analysis that only the heavy, thick pieces of glass were utilised by the Aborigines.

DISCUSSION – TYPE A GLASS

The ease with which broken bottle glass can be accidentally fractured along the margins is self-evident and this casts doubt on all pieces claimed as implements, except where the form is so refined that authenticity cannot be doubted, as in the case of Kimberley points (bifacial points with serrated edges).

The present analysis shows that the Type Aglass from Port Essington does possess formal attributes within the broad categories suggested. Little stress has been placed on the nature of the flaking, striking angles, usewear, et cetera, and this has been done deliberately. Until detailed studies can be made on natural fracture, and upon deliberate fracture produced in the laboratory, and the results compared with authenticated Aboriginal collections, little can be said on these finer points of glass working technology. The aim of the present analysis has been to authenticate the Port Essington collection on other grounds.

Before dealing with the results of the present analysis it is relevant to discuss a number of factors relating to glass artefacts in general. It is apparent that in most countries where indigenous stone using societies came into abrupt contact with Europeans, glass was often used as a substitute for stone. In Australia this has been noticed specifically in relationship to the pressure-flaked biface points from the Kimberley area, where the transition from stone to glass was made with little apparent alteration in technique or finished product. The technique for manufacturing this implement type from both stone and glass has been described by Mahony (1924) and Elkin (1948). While the implement type in glass has been reported as far south as Rottnest Island, near Fremantle in Western Australia (Serventy 1967), and is present in the upper levels of Ingaladdi (D. J. Mulvaney pers. comm.) to the east, its northern distribution does not apparently reach the Oenpelli area, although bifacial points do occur without serrated edges. No points of any description have been recovered at Port Essington.

Australian ethnographic literature contains a number of references to the use of glass by Aborigines. Backhouse (1843:433} illustrated a spear barbed with glass which he saw on the south coast of New South Wales; R. L. Dawson (1935:22) noted that bottle glass scrapers were used in the Clarence River area to sharpen spears; Scott (ML:44) and R. Dawson (1890:13–15) also mention Aborigines using glass. Jukes (1847:24) makes reference to the Torres Strait Islanders’ keen demand for bottles, which he suggests were broken and the fragments used for shaving and cutting hair.

Apart from Kimberley points, references to existing glass 87implements in Australia are less common. Tindale (1941) has published a ‘scraper’ from Kempton, Tasmania fashioned from the base of a glass bottle, which conforms to the shape of stone notched scrapers ‘of well-defined Tasmanian type’. Tindale remarks that no date can be ascribed to the glass, however from the illustration the bottle is apparently of English manufacture and dated definitely to post-1820. The terminal date could reach to 1870 for this specimen.

I have examined three hafted glass ‘knives’, two from the Queensland Museum and one from the Australian Museum, Sydney (discussed below in relation to cutting flakes). The only large collection of glass implements, so-called, was published by McCarthy and Davidson (1943) from Singleton, N.S.W. and comprises ‘a large series’ of side, end, concave and nosed ‘scrapers’ and ‘piercers’. I examined this collection in the Australian Museum and could not refute its authenticity on the form and flaking of these implements. However, bearing in mind Van Hoepen’s (1961:161) conclusions that trimming, identical in every respect to stone implements, may be produced fortuitously on broken glass, and the dubious nature of the area in which the Singleton collection was made, I visited the area accompanied by Mr Davidson in March 1967.

We collected 269 pieces of glass and 82 pieces of pottery in the general area indicated by Davidson. These were recovered from the eroding terrace along the river, immediately to the north of the railway bridge. The pottery included 63 pieces of white earthenware, all decorated by the transfer printed technique in predominantly floral patterns. Blue was the most common colour, but greens and browns were also present. Four clay pipe fragments bearing two makers’ names, ‘Burns Cutty Pipe’ and ‘McDougall of Glasgow’ were recovered. The glass was mainly ‘black’ glass, but opaque green, royal blue, light blue and purple glass also occurred, as well as modern beer bottle glass.

Only eight of the 269 pieces could be considered implements in terms of flaking. In McCarthy’s terminology one of these would be termed an ‘end-scraper’ and three ‘side-scrapers’. Of the others, three are of indeterminate form, and the eighth item is the flaked base of a beer bottle with moulded date underneath, 1938 (Figure 86). Thus the flaking is presumably the result of accidental breakage.

Figure 86. A non-artefact from Singleton, NSW, produced accidentally on a 1938 beer bottle base. See text for discussion.

This collection was made in a cleared field which must in the past have been heavily ploughed. The types of glass in this collection are the same as those in the Australian Museum and were collected in sufficient proximity to those of the 1943 collection to throw doubt on the authenticity of that collection. Although both collections were found in close association with Aboriginal stone artefacts, this connection could be spatial and not cultural. For some miles along the Hunter River stone implements can be found eroding out of the gravel layer a few inches below the topsoil. In the immediate area of this collection, although no houses exist at present, indications of early European structures (sandstock bricks and foundations) are visible and may have provided the source of this glass.

While it is possible, in view of the ethnographic evidence, that some of the 1943 Singleton collection is authentic, the demonstration that some of it is not must cast doubt on the entire collection. The point of this discussion is that the immediate environment offers an alternative explanation. The high degree of specialisation of this glass industry, containing only ‘scrapers’ and ‘piercers’ is also suspicious, since these ‘implements’ are the easiest types to produce fortuitously. In contrast to the Port Essington collection, neither the 1943 collection nor my own collection from Singleton contains any struck flakes.

Unlike the environment at Singleton, the environment at Port Essington provides few natural agencies to explain the flaked glass. The area has been mostly deserted since 1849; no clearing or ploughing has occurred since then and there are no roads in the area. Cattle, together with damage caused during the initial dumping of the glass are the most likely natural explanations, yet these seem an insufficient explanation given the large number of items in the collection.

Also of significance is the percentage distribution of Type A glass around the settlement (Table 74), where it can be seen that the three areas with the highest proportion of Type Aglass are the two Aboriginal middens and VMQ, where excavation demonstrated that Aborigines sat outside the structure during British occupancy and made implements. The authenticity as artefacts of glass pieces found stratified in an undisturbed Aboriginal midden cannot really be doubted.

A recurring theme noted in the analysis of the material has been the tendency to utilise the heavier sections of the bottles for the manufacture of artefacts. This tendency has been noted elsewhere in the world, by Sir Bartle Frere amongst the Bushmen (Beaumont 1961:161), who purchased cheap German scent because the bottles, ‘thickened towards the lower part … could, by a blow in a particular direction, be splintered so as to form excellent arrow-heads.’ E. H. Man (1932:160–61) writing on the Andaman Islanders also noted their use of glass ‘chips’ and stated, ‘the method by which they are obtained is the same [as flint], the thick lump of glass forming the bottom of beer and wine bottles being selected for the purpose, and never the thinner portions.’

Against this background the typological analysis has demonstrated the most significant trends. Amongst the base cores several formal patterns were noted.

• The base itself is almost always broken where apparent utilisation of the edge has taken place, whereas bases are less seldom broken when deliberate flaking is absent.

• There appears to be some relationship between wall height and the amount of base remaining on apparently utilised items.

• If the flaking was fortuitous it would be reasonable to expect internal unifacial flaking to occur at least as often, if not more often, than external unifacial flaking, since the blow to produce the latter has to be made on the internal 88wall surface. At Port Essington external unifacial flaking is more common.

• Where flaking does occur, it most commonly appears along the total remaining wall edge, and this is unlikely to occur fortuitously.

Although bifacial flaking occurs only 65 times in the total collection of Type A glass, the fact that it is present is a strong indication of deliberate fracture. I carried out a series of experiments by smashing glass on a concrete path, treading on glass, hitting pieces of glass together, etc., and found it impossible to produce bifacial flaking of the size and regularity that occurs in the Port Essington material.

The analysis of the cutting flakes provided a significant piece of evidence for judging the authenticity of the collection, this being the size of the utilised struck flakes. In my experiments breaking glass I found that flakes with bulbs of percussion could be manufactured accidentally, but never of the size of the Port Essington cutting flakes, unless a deliberate striking technique was employed. In the archaeological collection some flakes were shown to be much longer than they are broad, and on a base core from VM/8/1 two flake scars measuring 43 mm by 16 mm and 41 mm by 15 mm were noted. On a base core from VM/9/1 a flake scar measuring 52 mm by 12 mm was recorded, and part of the flake taken from this base was fitted back onto the core. In all these examples, the detached flake was extremely thin and it seems likely that these flakes could only have been produced by using a pressure flaking technique.

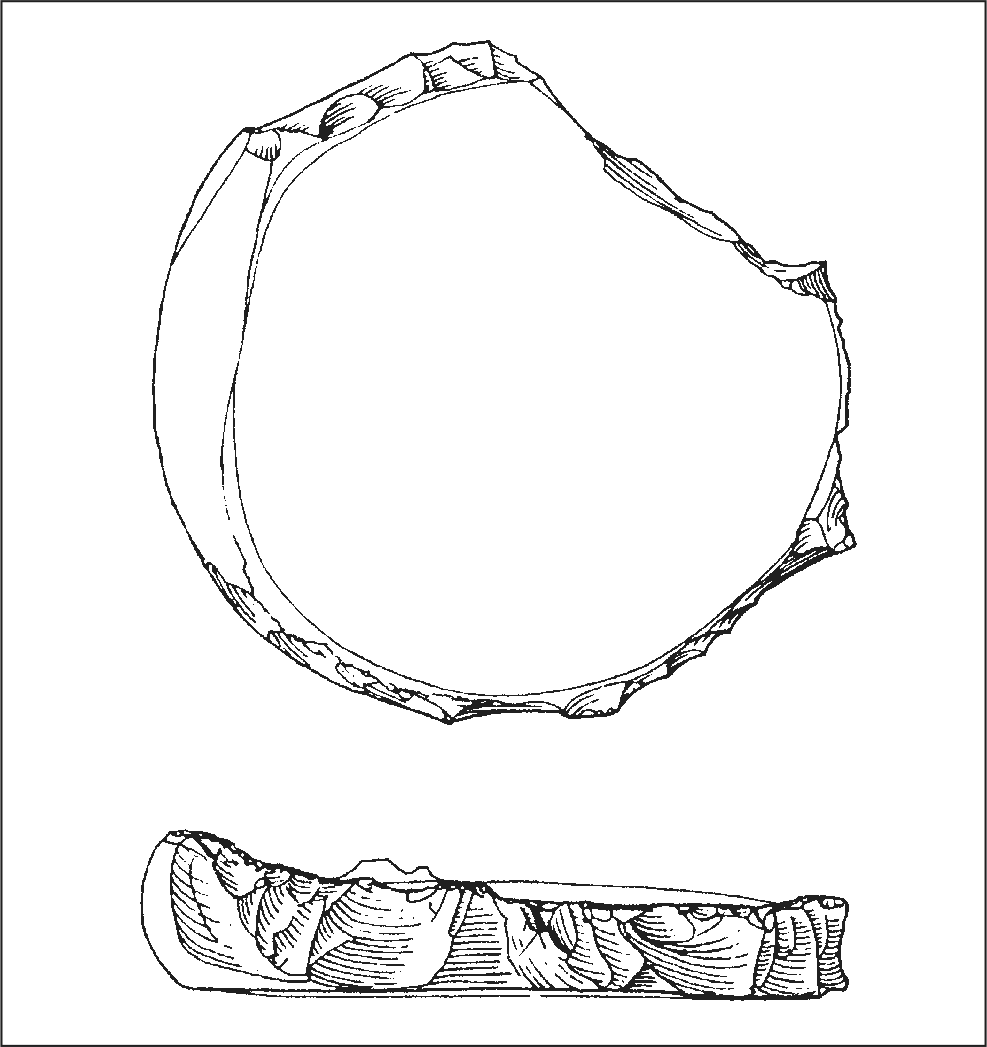

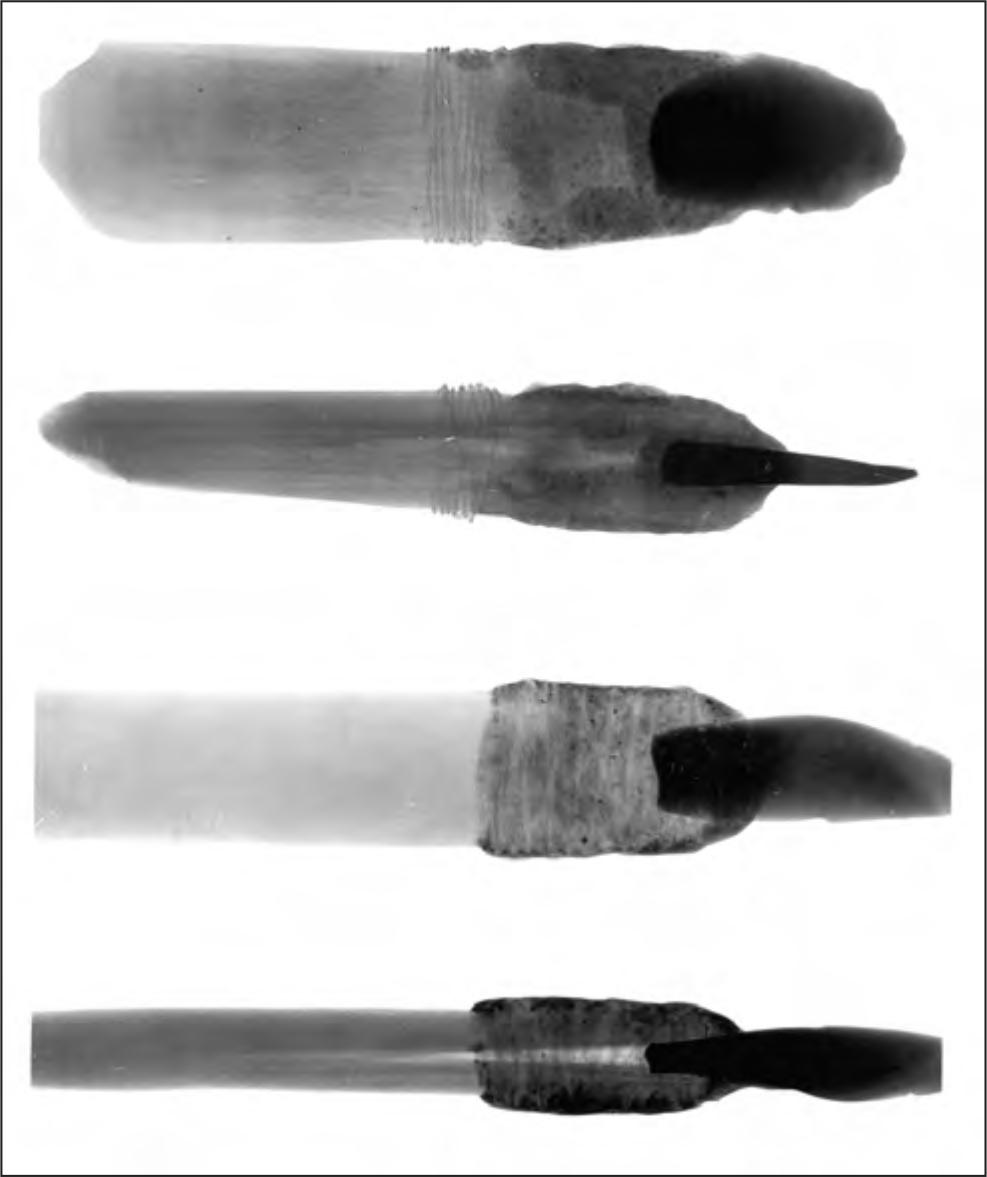

Figure 87. X-rays of two hafted glass cutting flakes from north-west Queensland now in the Queensland Museum. Top Q.E.588, bottom Q.E.2291.

As discussed, in the course of examining museum collections three glass ‘knives’ were examined. Specimen E.54602 in the Australian Museum collection, has as its provenience ‘Central Australia’ and has a struck flake of glass which measures 32 mm in length mounted sideways onto a handle with gum. Two hafted glass implements from north west Queensland are in the collection of the Queensland Museum (Q.E.588, Q.E.2291). X-ray photographs show that these two knives were made by inserting struck flakes of glass into split wooden handles, compacted with string and gum (Figure 87). One flake measured.59 mm by 20 mm and the other 43 mm by 28 mm. The important point about each of these three specimens is that none has retouched edges, although all bear signs of usewear similar to those from Port Essington. On the basis of only a single cutting flake from Port Essington (VAMII/1/1(1)) with traces of gum on the surface, no claim of direct evidence for hafting of the Port Essington cutting flakes can be made. However the use of non-retouched flakes in ethnographic specimens lends support to the authenticity of the Port Essington cutting flakes and their classification as a distinctive glass tool type.

The analysis of the retouched implements points up the difficulty of verifying the authenticity of claimed glass artefacts. Any section of bottle glass placed on a hard surface and with pressure applied against the natural curve of the glass will produce ‘scrapers’. But taking into consideration

• the average weight of the claimed artefacts compared to the wider collection

• the technology recorded for both flakes and cores

• the presence of some bifacial working

• the difference in edge shapes between ‘side’ and ‘end’ scrapers

• the presence of retouch on some cutting flakes, and

• the environmental setting

then the authenticity of glass implements at Port Essington is not open to serious doubt. At the same time there appears to be no way of positively identifying single glass artefacts, but commonsense should suggest the probable validity in terms of the above discussion.

At Port Essington, then, we may safely assume that the Aborigines quickly utilised this new material in an area lacking suitable stone. The implications of the archaeology are that this material was collected from the European rubbish dump and often modified there, and then taken onto the Aboriginal midden for utilisation for cutting and scraping activities. This analysis reflects some degree of specialised usage of the bottles available but the technology was not complex, as, for example, when compared to Kimberley bifacial point production. It is best seen as a transference of stone techniques to glass in an area where, from the present archaeological evidence, stone played a minor role in the technology and economy of the Aborigines, and what stone used was imported (see Chapter 5).

TYPE B GLASS

A total of 239 pieces of glass were initially sorted as items which would assist in the shape classification of the glass from Port Essington. The majority of these pieces are fragments of dark green (‘black’) bottle glass, and consist of base, neck and rim fragments. In addition, 15 prunts, or glass seals, were recovered, and a number of other items made of glass.

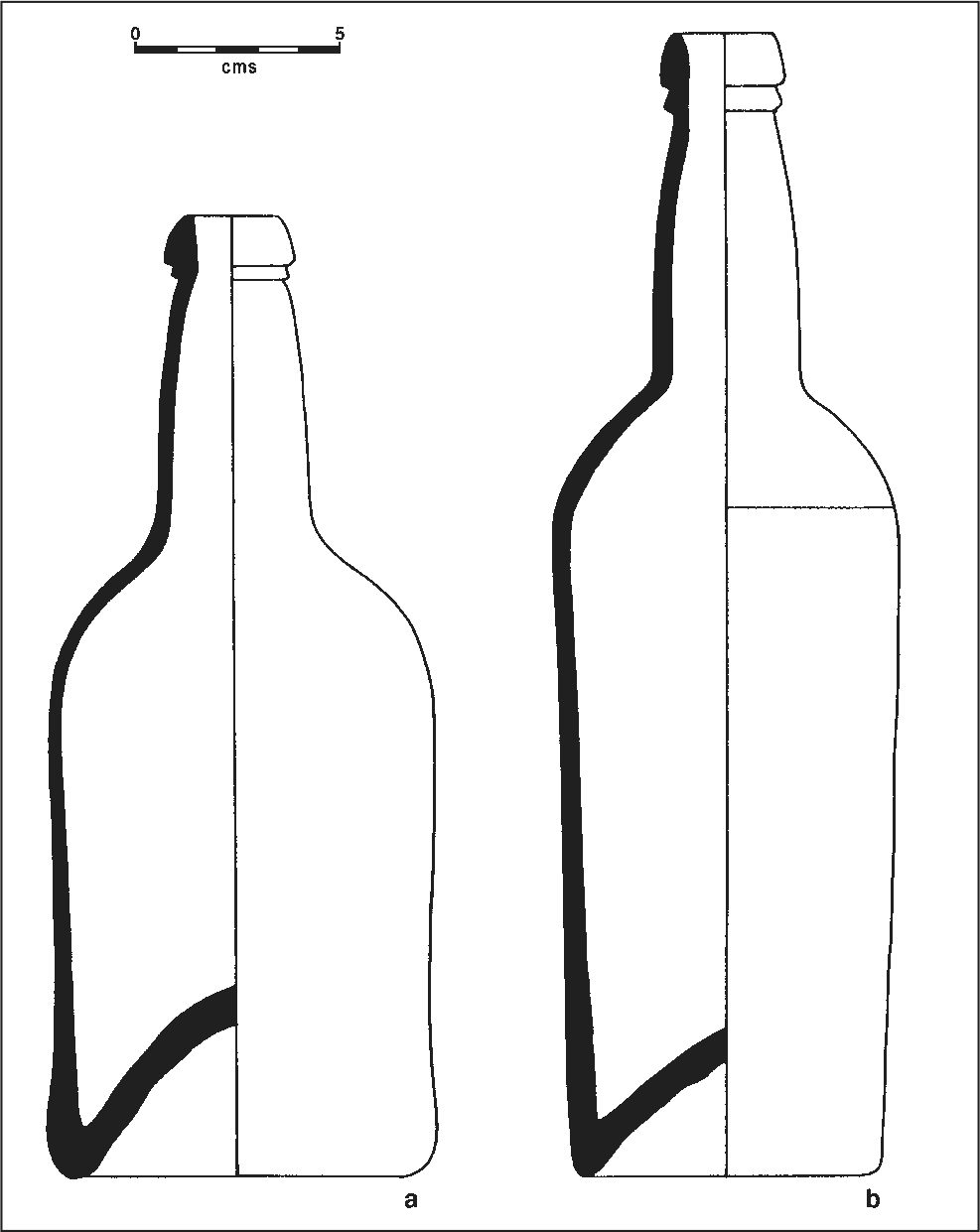

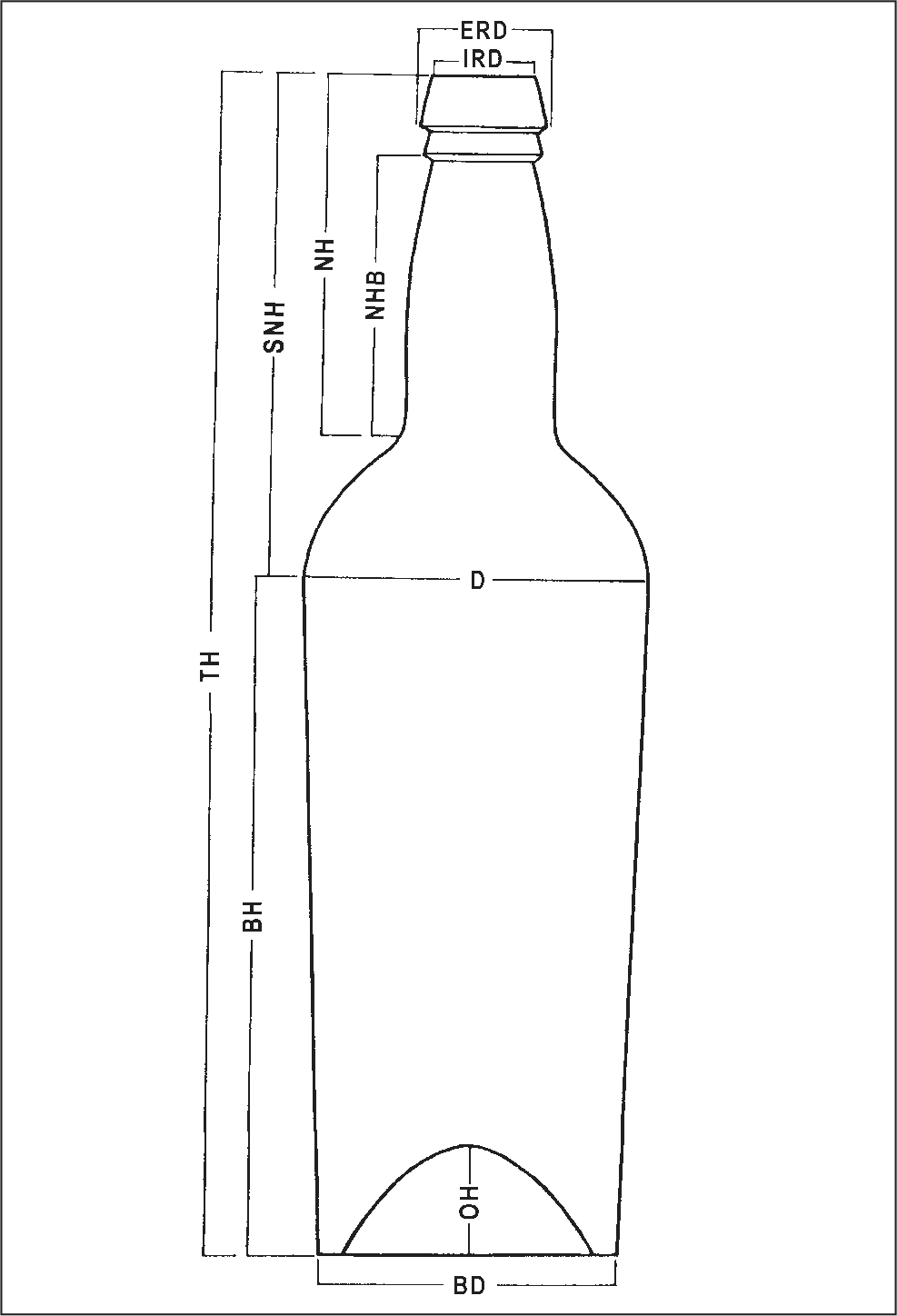

Two whole bottles (Figure 88) and a third with the lip missing were recovered from the excavations and these appear to reflect the main types in the collection as a whole. Figure 89 illustrates the measurements taken on both the whole bottles and the fragments where possible.

In all, measurements were taken from 85 bases and 134 rims and necks. No measurement was taken unless more than 50% of the base or rim was present so that these figures represent minimum numbers. In view of the utilisation of bases by the Aborigines it is not surprising that almost twice as many rims as bases are represented in the present category. While the collection represents a minimum of 134 bottles, an 89upper limit is difficult to calculate. The mean average weight of the two whole bottles is 726.6 gm. The calculated weight of 134 bottles would then be 97364.4 gm, which is in excess of the total weight of glass recovered (96580 gms). However, from the rim fragments not included in the analysis, perhaps an additional 30 bottles are represented. Clearly, calculations on weight are simplistic and to be avoided.

Figure 88. Complete bottles from Port Essington. Left V/GEN SUR/Hospital (39), right VM/14/1 (37).

Figure 89. Measurements taken on Type B glass where measurable. Key: TH: total height; SNH: shoulder and neck height; NMB: neck height below rim; OH: omphalos or kick height; D: maximum diameter; BD: base diameter; ERD: external rim diameter; IRD: internal rim diameter.

A large majority of the bottles in the collection are of English manufacture. There appear to be no glass bottle manufacturers in Australia until the last quarter of the nineteenth century. Trade directories list manufacturers in Sydney and Melbourne in 1879, but large scale production of bottles in Australia did not take place until the twentieth century (H.L. Brown, Museum of Applied Arts and Sciences, Sydney pers. comm.). Dutch bottles (square case bottles, presumably but not certainly containing gin) and wine bottles in a lighter green glass, perhaps French (see bottle seals, below), are also in the collection.

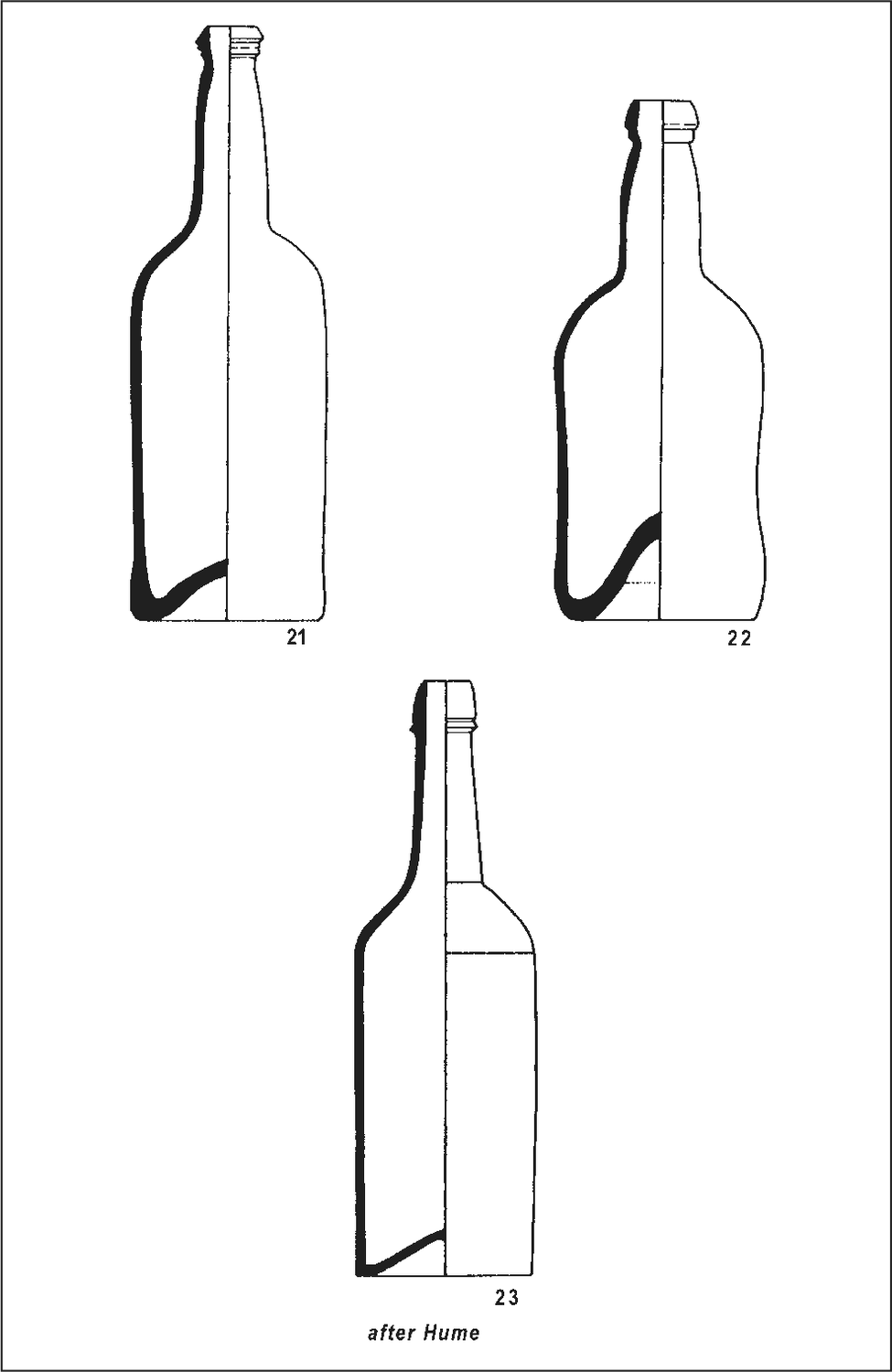

Figure 90. Bottle shape types from Hume’s (1961) classification. Number 21 is a free-blown evolved cylindrical form with tall body and short neck, with a thickened mouth tooled downwards over the string-rim. Number 22 is a free-blown squat cylindrical form with short convex neck, dated to c. 1790-1820, see for comparison Figure 88a. Number 23 is a machine-made bottle made by Ricketts of Bristol and dated to c. 1814-1853.

The best account of English bottle manufacture has been written by Hume (1961) where he presented a general typology to illustrate the development of English bottle shapes from about 1650 to 1850 (1961:102–5, figs. 3–5). Of immediate interest here are numbers 21 to 23 of Hume’s classification (Figure 90). Number 21 represents the evolved cylindrical form with tall body and short neck. Of importance in this item, where the string-rim had previously been a single 90glass strip around the neck, it now becomes a thickened mouth tooled downwards over the string-rim. This variation increases in number 22 which is a squat cylindrical form with short convex neck. Hume dates number 22 to about 1790–1820, and this example is closely related to one of the whole bottles from Port Essington (V/GEN SUR/HOSPITAL (39) (Figure 88a). Number 23 in Hume’s typology is a machine-made bottle made by Ricketts of Bristol and dated by Hume to about 1814–1853.

The invention of machine-made bottles was important, not only because of improved manufacture, but also because size could be standardised. According to Hume (1961:94) the technique was perfected in 1811 by Jacob Ricketts and his son Henry, and the latter enrolled a patent for this bottle in 1822 (Ricketts 1822). By this method, the body of the bottle was formed by blowing the glass into the mould, and the shoulder and lower neck was formed by the opening top section of the mould. This is apparent from the illustration attached to Ricketts’ patent, which shows that the top section of the neck was free-blown, and that the string-rim must have been attached later, not as Hume suggests (1961:94), in a single operation.

Of the two whole examples in the present collection, one is a blown bottle, the other bears the mould marks at the junction of the shoulder and body wall, and running vertically up opposite sides of the shoulder and lower neck (Figure 88b). A large number of examples of this technique are found in the Port Essington collection. However, no instance of a moulded string-rim was present in the collection, all rims having been attached after the bottle was made. Olsen noticed a similar technique on a collection of bottles from Florida (Olsen 1965:105–7) which included Ricketts bottles, and were dated to the period 1835–1842. Olsen identifies this technique by the uneven appearance of the rim which ‘fuses with the mold seam’. However, from his illustration, 2c, he appears to confuse the mould seam with a striation on the bottle neck often found on these bottles.

The form of the kick on the Ricketts bottles appears fairly standard, being relatively shallow, and having the name of the maker moulded on the base. This practice was in use in the Ricketts factory from 1822 at least, since it is illustrated in Ricketts’ patent. This base appears to have a central nipple on some examples but not on others. This form of base appears to be almost completely absent in the Port Essington bottles, where the high conical kick is the form employed, usually with the central indentation of the pontil present. Thus I assume that specific Ricketts bottles are not present in this collection, but instead that the majority of the collection represents an early form of machine-made bottle made essentially in the technique patented by Ricketts, and using a simpler form of ‘pricker-up’ which continued to produce the high conical kick found on earlier blown examples.

Rims

Figures 91 and 92 present a classification of rim shapes present in the Port Essington collection. However, Hume’s (1961:102) warning that bottles are often far from regular and that profiles may alter depending on which side a bottle is viewed from must be emphasised. While such discrepancies were overcome to some extent by machine manufacture, variation still occurs. However, with machine made bottles, large collections may afford reasonable information from metrical analysis, as the Port Essington bottle fragments demonstrate. While no two are exactly alike, the bottles from this collection possess the same sort of relationships as pieces of hand-made utilitarian pottery where the potter is trying to replicate a single form.

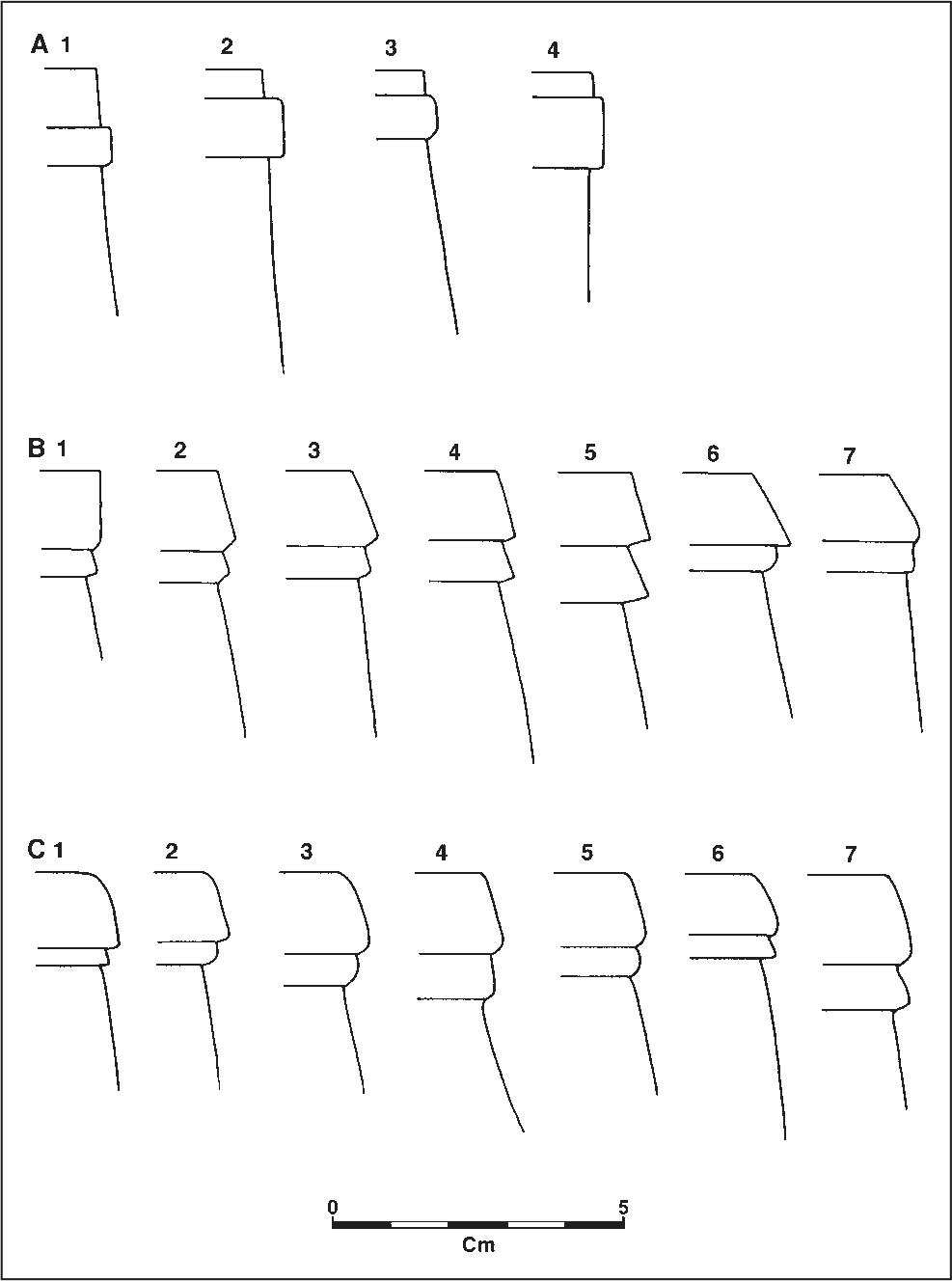

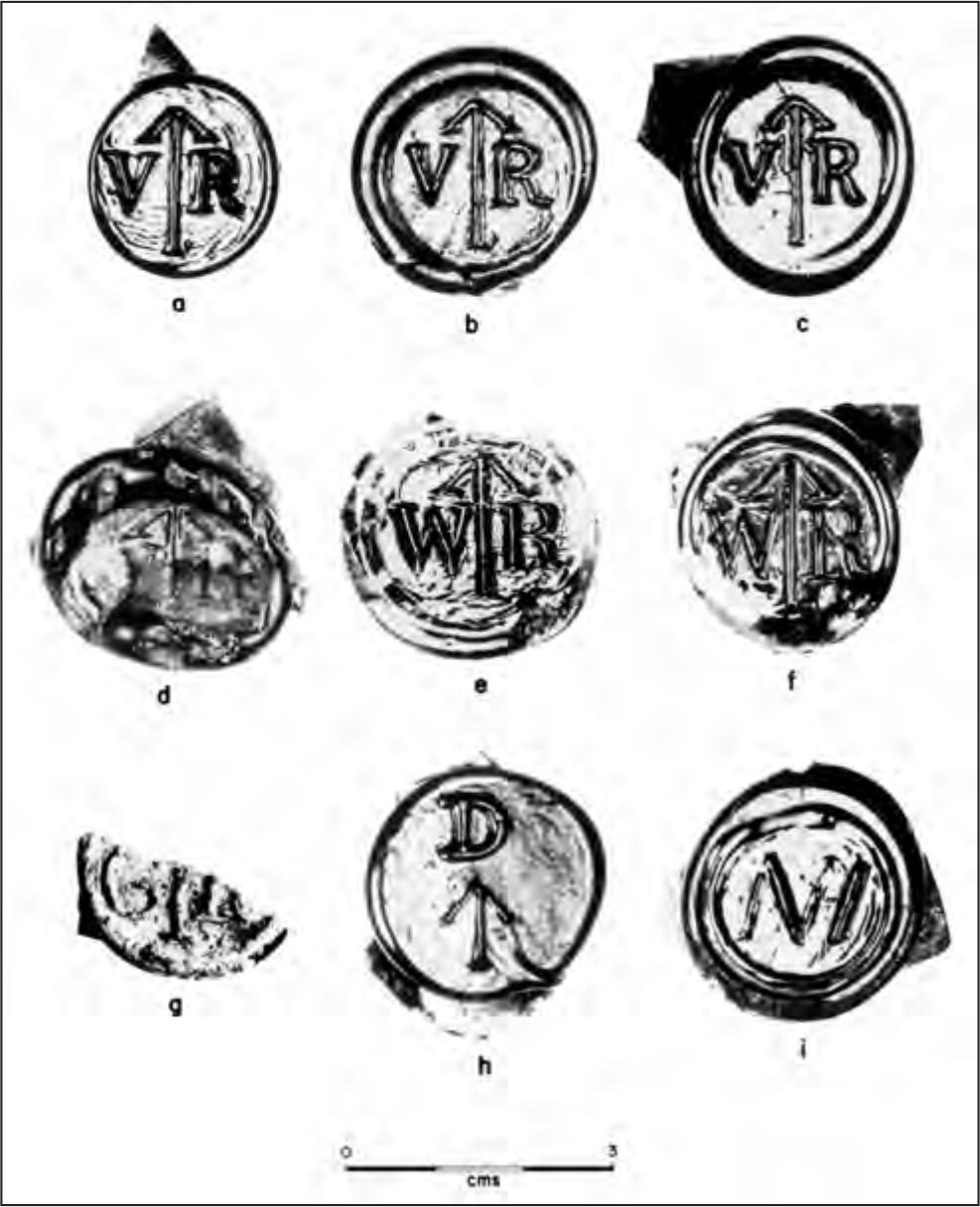

Figure 91. Rim types from the Port Essington collection.

The rims in the present classification have been arbitrarily arranged on morphological grounds. The A series (Figure 91) illustrate the variation in simple strip string-rims which are normally associated with free-blown bottles, although the items in this category are too fragmentary to determine whether any come from machine made bottles. Klein (1952:128, fig. 3.2) illustrates three examples to demonstrate the difference between English and Continental strip string-rims. In the Continental type, the rim is carelessly applied, the end often overlapping the beginning, and this occurs in the present collection, particularly in Figure 91 A1, but this evidence is too flimsy to ascribe Continental origin to the items in this category.

More distinctive are the Continental bottles with long necks, narrow at the bottom and bulbous at the ‘top’ (Klein 1952: figs. 21, 29) which bear this type of Continental rim. This type is certainly present at Fort Dundas on Melville Island (Specimen 11-3633 from the Pilling Collection in the R.H. Lowie Museum of Anthropology, Berkeley, California; plus two items I collected at Fort Dundas on Melville Island in 1967). Some of the A1 series from Port Essington are indistinguishable from these in terms of the string-rim. Thus the possibility of Continental, probably Dutch, manufacture should not be overlooked for these items, and Hume who commented on the Port Essington bottles (pers. comm.) believes that all the A series string-rims from Port Essington are from bottles of non-English origin.

Series B and C (Figure 91) form the bulk of the collection and illustrate the wide range of variation in bottle rims in the collection. Unless whole examples are present it is impossible to relate these rims to free-blown or moulded bottles. Of the two whole bottles in this collection, the free-blown example has rim shape C1; the moulded example has rim shape C7. The sizes of the rims differ greatly but there is nothing to suggest that this relates to methods of manufacture. 91

Figure 92. Case bottle rim types from the Port Essington collection.

As discussed above, all these rims appear to have been applied after the bottle was made, presumably by using a hot rolling technique. None of the examples use the method described by Hume (1961:105, item 22) of rolling the lip of the neck down over the string-rim while the glass is still hot, although one example of this technique was collected at Fort Dundas by John Morris of Darwin, who kindly lent his entire collection for study.

Series D (Figure 92) represents rims from case bottles. One seal in the collection marked ‘AH’ can be identified as a Dutch manufacturer and this seal presumably came from a case bottle, so that this collection may comprise either Continental bottles, or both Continental and English types. In general the group is reasonably homogeneous, except for D4 which possesses a longer neck than the other examples. I have located no parallels for this long variety.

Types E to I illustrate all the other variations of ‘black’ bottle rims in the collection and represent single Items except for E, in which category there are four examples.

Types J, K and L are all manufactured in light green glass. J and L are bottle rims; K is a narrow jar mouth. Type M is a bottle rim in clear glass.

The numerical division of the collection of 134 rims into these categories is given in Table 84.

Table 84. Glass Type B: numerical distribution of rims according to type.

| A1 | A2 | A3 | A4 | Total | |||||

| 5 | 2 | 2 | 1 | 10 | |||||

| B1 | B2 | B3 | B4 | B5 | B6 | B7 | |||

| 1 | 5 | 10 | 7 | 2 | 1 | 2 | 28 | ||

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | |||

| 14 | 8 | 2 | 8 | 6 | 8 | 17 | 63 | ||

| D1 | D2 | D3 | D4 | ||||||

| 10 | 1 | 8 | 2 | 21 | |||||

| E | F | G | H | I | J | K | L | M | |

| 4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 12 |

| Total | 134 |

Two measurements (Figure 89, ERD and IRD) were made on this collection. This was done initially for each type, but the results were so similar within series that it appeared reasonable to group the series. Tables 85 and 86 show the results, giving the maximum and minimum values, mean average, and standard deviation.

Table 85. Glass Type B: external rim diameter measurements (mm) according to rim type.

External Rim Diameters (mm)

| Series | No | Maximum | Minimum | Mean | SD |

| A | 10 | 43 | 30 | 32.5 | 3.7 |

| B | 28 | 36 | 27 | 32.3 | 1.6 |

| C | 63 | 36 | 28 | 32.0 | 1.6 |

| D | 21 | 45 | 38 | 41.5 | 1.7 |

| E | 4 | 34 | 28 | 31.8 | 2.3 |

| F | 1 | 30 | |||

| G | 1 | 37 | |||

| H | 1 | 30 | |||

| I | 1 | 34 | |||

| J | 1 | 20 | |||

| K | 1 | 46 | |||

| L | 1 | 25 | |||

| M | 1 | 19 |

Table 86. Glass Type B: internal rim diameter measurements (mm) according to rim type.

Internal Rim Diameters (mm)

| Series | No | Maximum | Minimum | Mean | SD |

| A | 10 | 24 | 19 | 19.9 | 2.4 |

| B | 28 | 23 | 16 | 20.5 | 1.5 |

| C | 63 | 24 | 16 | 20.2 | 1.5 |

| D | 21 | 23 | 14 | 17.9 | 2.1 |

| E | 4 | 20 | 18 | 19.3 | 0.8 |

| F | 1 | 19 | |||

| G | 1 | 20 | |||

| H | 1 | 20 | |||

| I | 1 | 18 | |||

| J | 1 | 9 | |||

| K | 1 | 31 | |||

| L | 1 | 11 | |||

| M | 1 | 15 |

Excluding the single items from these tables, it appears that while exact measurements may mean very little, each group is sufficiently homogeneous to suggest meaningful ranges for bottle rims in this period. Series B and C are almost identical, and selecting the larger types out of these two groups, there is little difference in the ERD and IRD measurements for the larger and smaller types. The A series shows the greatest variation, but if the single item in Type A4 (already discussed as large and atypical) is removed the ERD measurements form a closer group (Table 87).

Table 87. Glass Type B: external rim diameter measurements (mm) for Type A, excluding A4.

| No | Maximum | Minimum | Mean | SD |

| 9 | 34 | 30 | 31.3 | 1.4 |

Where the necks were intact (sample = 40) two further measurements were made on this group, neck height (NH) and neck height below rim (NHB) (Tables 88 and 89).

These tables indicate a fairly wide variation in neck height which apparently cannot be explained by the varying heights of rims. That is to say, that no closer standardisation of neck heights could be obtained for the individual types in any series by grouping the larger and smaller rim types together. The 92figures do, however, provide measurement ranges for future comparative study.

Table 88. Glass Type B: neck height measurements (mm) according to rim type.

Neck Height (mm)

| Rim Type | No | Maximum | Minimum | Mean | SD |

| B | 7 | 92 | 76 | 87 | 5.2 |

| C | 15 | 97 | 74 | 86.5 | 5.0 |

| D | 16 | 45 | 17 | 29.9 | 12.0 |

| F | 1 | 121 | |||

| G | 1 | 84 |

Table 89. Glass Type B: neck height below rim measurements (mm) according to rim type.

Neck Height Below Rim (mm)

| Rim Type | No | Maximum | Minimum | Mean | SD |

| B | 7 | 74 | 57 | 68.6 | 5.6 |

| C | 15 | 80 | 57 | 68.7 | 5.4 |

| D | 16 | 38 | 10 | 22.9 | 10 |

| F | 1 | 101 | |||

| G | 1 | 58 |

Bases

Of the 85 ‘black’ glass bottle bases in the collection, two are moulded, eight are square case bottle bases and 75 have the conical kick, usually associated with free blown bottles, but which in the present collection must be associated in fairly large numbers with the moulded bottle technique as well (see discussion on Ricketts bottles above). As previously stated, many of these bases have a pontil indentation in the centre of the kick, which in the case of the moulded examples is presumably made by the pricker-up, described in Ricketts’ patent.

Two measurements were made on the bases in the collection, the diameter at the base (BD) and the maximum height of the omphalos or kick (OH). It was found that both measures produced a series of slightly different measurements when repeated. Thus these measurements were seldom as exact as reported here; for example a second BD measurement taken at right-angles to the first might give a difference of 2 mm. Thirteen items could not be measured, reducing the sample to 62. Table 90 summarises the results.

Table 90. Glass Type B: distribution of circular bases according to base diameter (mm) and kick height (mm).

| Base Diameter | Sample Number | Kick Heights | Not Measured | |||||||

| 13 | 21 | 25 | 30 | 34 | 40 | 44 | 53 | |||

| 70 | 1 | 1 | ||||||||

| 73 | 5 | 1 | 4 | |||||||

| 78 | 36 | 7 | 10 | 5 | 3 | 9 | 1 | 1 | ||

| 82 | 23 | 1 | 6 | 2 | 4 | 5 | 5 | |||

| 90 | 8 | 1 | 1 | 6 | ||||||

| 96 | 1 | 1 | ||||||||

| 113 | 1 | 1 | ||||||||

| Total | 75 | 1 | 9 | 11 | 11 | 5 | 13 | 7 | 5 | 13 |

From this analysis, it can be seen that there is little apparent correlation between the base diameter and the height of the kick except that 17 examples of the 36 with a base diameter of 78 mm have a kick height of either 21 mm or 25 mm, while only 1 example of 23 items with a base diameter of 82 mm has a kick height less than 30 mm. Together these two groups comprise almost 80% of the collection and suggest a norm for base diameter for the bottles of this period.

Of the five examples with a base diameter of 77 mm, four have a particularly high kick (53 mm). These items are in a lighter green glass than the majority of the collection and all came from a single area, VM. In this area a number of French wine bottle seals were recovered in similar coloured glass, and it is reasonable to assume that these bases belong to French wine bottles.

Of the eight examples of case bottle bases all are square. One example is 69 mm along each side and has a single line diamond-shaped mark moulded on the base. The other seven all measure 74 mm along each side and four moulded base marks are present; two examples of a single-lined cross, one ‘asterisk’ mark, and a single-lined square. One example with a high (20 mm) kick and bearing a pontil mark is present. Such moulded base marks as described here are of little value for identification and were used from the late eighteenth century onwards (Hume 1961:93, fn 17).

In view of the introduction of the Ricketts’ moulding technique so early in the nineteenth century, and the undoubted presence of bottles made in a similar manner at Port Essington, it is surprising to have an almost total lack of ‘black’ glass moulded bottle bases in the collection. Only two examples are present, both having a base diameter of 80 mm (a size not found in the collection of bases with conical kicks); one has a kick height of 8 mm, the other of 18 mm. The example with the lower kick has a central nipple, a feature missing on the other example. In view of the general absence of conventional moulded bases in this collection it is reasonable to conclude that other moulded bottles present at Port Essington almost always possessed bases with conical kicks. The two whole examples in the collection certainly possess this sort of base. Apart from these ‘black’ bottle bases, however, five moulded bases were recovered, manufactured in a light green glass. Two examples are cylindrical with a diameter of 78 mm and a kick height of 13 mm. The remaining three examples are square with sides measuring 68 mm, but with the corners cut (making the cross-section an uneven octagon). Each has a round kick 17 mm high.

COMPLETE BOTTLES

As mentioned above two whole bottles and a third with the rim missing were recovered from the excavations.

1. V/GEN SUR/HOSPITAL (39) Figure 88a.

This item is a free blown bottle, with the rim shape Type C1, its weight is 691.8 gm and has a volume of 700 ml, measured to the base of the neck. The measurements delineated in Figure 89 are as follows: TH: 237 mm; BH: 124 mm; SNH: 113 mm; NH: 81 mm; NHB: 63 mm; OH: 44 mm; BD: 90 mm; D: 93 mm; ERD: 32 mm; IRD: 20 mm.

In general this bottle is very uneven; it rocks on its base and is not symmetrical. It is typical of Hume’s type No. 22, to which that author ascribes a date 1790–1820 (Hume 1961:105).

2. VM/14/1 (37) Figure 88b

This bottle is moulded in the Ricketts’ method, but with a high conical kick. The shape of the rim is Type C7; weight 762.0 gm; volume 710 ml, again measured to the base of the neck. Other measurements are: TH: 288 mm; BH: 159 mm; SNH: 129 mm; NH: 90 mm; NHB: 65 mm; OH: 30 mm; BD: 78 mm; D: 85 mm; ERD: 30 mm; IRD: 20 mm.93

At present no-firm date can be ascribed to bottles of this type. A terminus ante quem non of 1811 might be applied on the basis of the moulded body but this is of little value in determining a close date of manufacture. As discussed above, the practice of subsequently attaching string-rims by hand to otherwise moulded bottles has been noted in Florida (Olsen 1965:105–7) in a collection dated to the period 1835–1842. This date range coincides nicely with the present collection, so that the association of these two techniques might have chronological significance in a typological sense.

Figure 93. French bottle seals from the Port Essington: a) VM/11/1; b) VM/SUR/67; c) VM/12/1 (100); d) VM/6/1 (1); e) VM/S/W (1); f) VAMII /2/1 (1).

3. VM/13/1 (27)

This bottle is complete except that the rim has been broken off. It has been made by the same technique employed for VM/14/1 (37) but the glass is amber rather than black. Its weight is 646 gms; volume 730 ml. Other measurements are: TH: 304 ± 5 mm; BH: 163 mm; SNH: 135 ± 5 mm; NH: 95 ± 5 mm; NHB: 80 mm; OH: 30 mm; BD: 78 mm; D: 85 mm. This bottle is slightly larger than VM/14/1 (37).

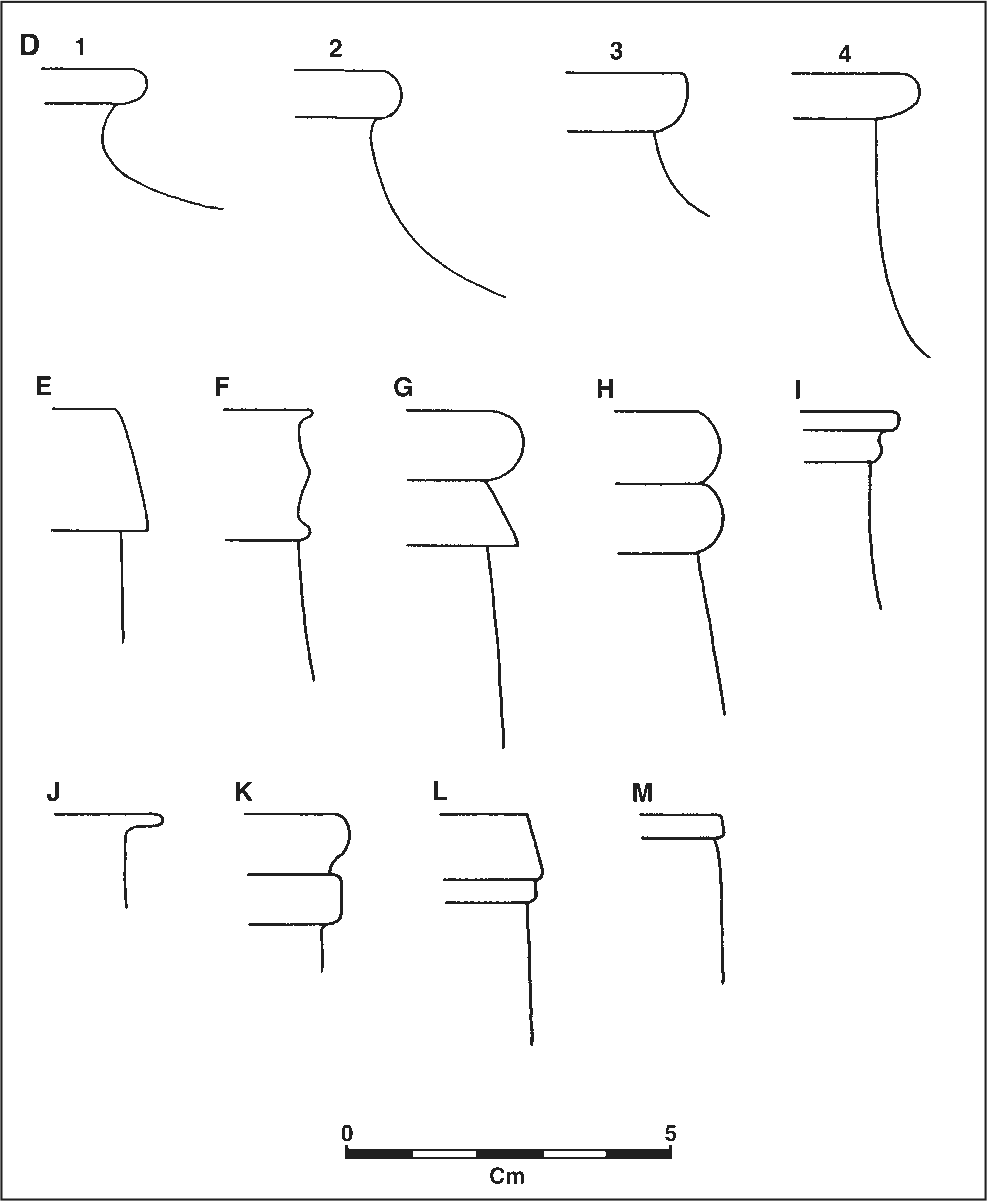

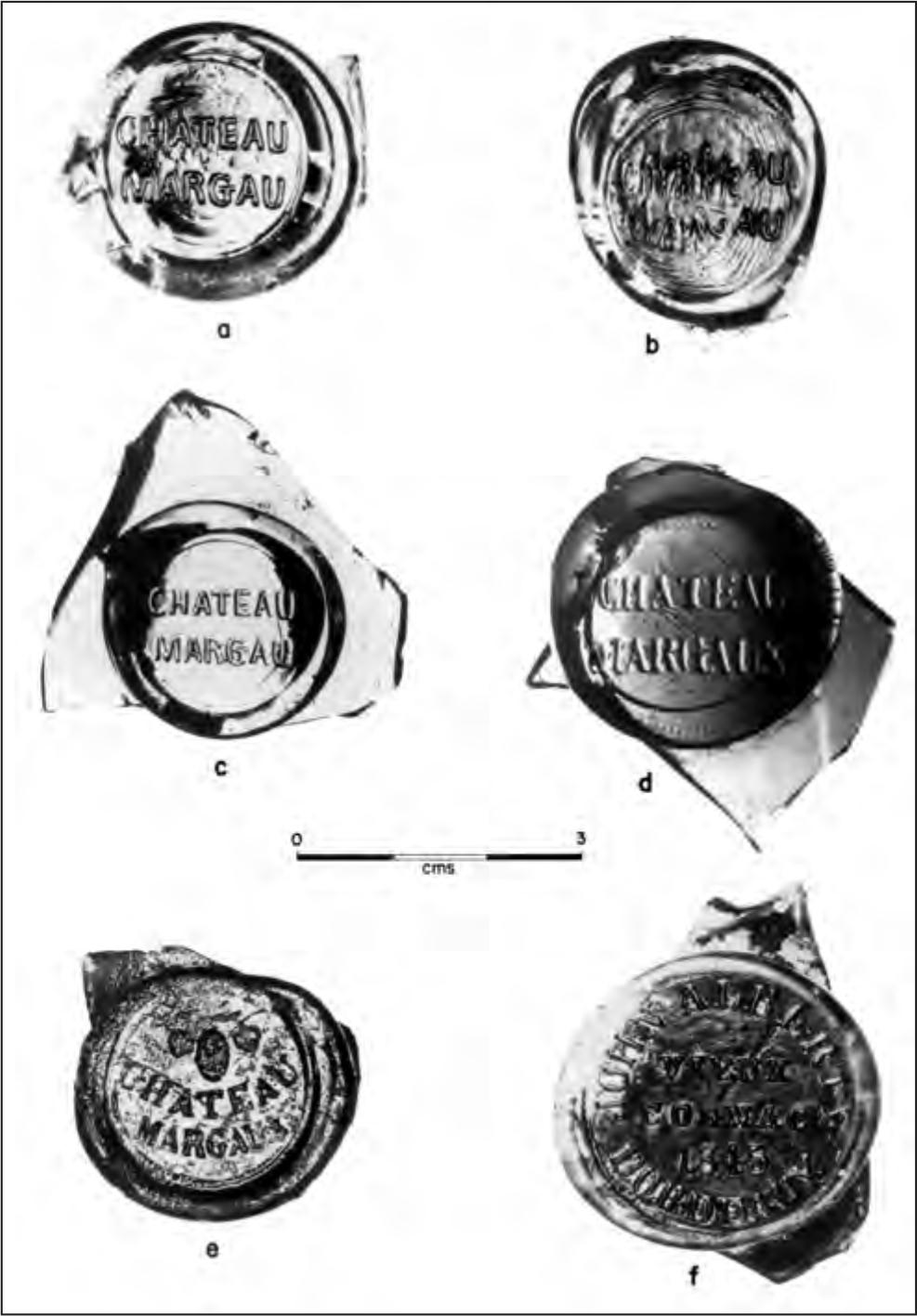

GLASS BOTTLE SEALS

From the middle of the seventeenth century until about the 1870s bottles sometimes bore on the shoulder a glass prunt or seal which served the purpose of a label. These were inscribed with a crest, a name or initials, sometimes a date, or an address. Ruggles-Brise (1949:15) has divided these seals into two groups; proprietary seals and factory seals. In the later nineteenth century the use of these seals dies out, presumably because of the introduction of moulded lettering on bottles, although Hume (pers. comm.) reports a bottle with a glass seal made in France in 1905. Some present-day liquor bottles still bear moulded versions of these seals as decoration.

Fourteen seals were recovered from the Port Essington excavations, six from VM, four from VSD, two from VH, one from VAM II, and one in the general surface collection. These fall into three distinct groups.

The Château Margaux Seals (Figure 93)

Five seals bear various inscriptions of this Bordeaux vineyard. Three are stamped ‘CHATEAU MARGAU’, a fourth ‘CHATEAU MARGAUX’ and the fifth ‘CHATEAU MARGAUX’ beneath a grape cluster. The last example is in ‘black’ glass, all the others being light green.

Château Margaux, from the Médoc region of Bordeaux achieved lasting fame when the Bordeaux Wine Official Classification of 1855 was created for the Paris Exposition of that year. The classification named the Grand Crus Classés (great classified growths) in five divisions. Château Margaux was one of only four wines to be assigned the ultimate Premier Cru (first growth) status in a classification that remained unchanged for over a century.

It was thus a very superior wine to be drinking at Port Essington.

Unfortunately the vineyard holds no records that might give a closer dating to these seals than can be arrived at archaeologically.

At least one other seal in the collection may be regarded as being related to these French wine bottle seals. This is inscribed ‘John Alberty Bordeaux Vieux Cognac 1815’ (Figure 93-f). See also item VM/11/1 (29), a glass stopper, discussed below.

It is highly doubtful that the British government would supply outposts such as Port Essington with vintage French wine, nor is there any obvious trade source to account for this commodity. The answer is found in the French account of the visit of the Astrolabe and Zelée to Port Essington in April 1839. The leader of the French expedition, Dumont d’Urville related that on 7 April:

A cinq heures nous étions tous réunis à la table de M. Bremer; il avait mis toute la colonie à contribution pour nous traiter splendidement. Si nous en avions été réduits à cela, nous eussions couru risque de faire pitense chère, mais grâce à de bonne viande de buffle, un superbe dindon, et d’excellentes volailles provenant de Timor, le tout assaisonnè de vieux vin de Sauternes et de Bordeaux, nons eûmes un charmant dîner (d’Urville 1841-55 (VI):280 n.19).

[At 5 o’clock we (d’Urville, his officers and one assumes the British officers) were all together at Monsieur Bremer’s table. He had gotten the whole settlement to contribute to a splendid treat for us. If we had been reduced to this, it would have been woeful; but, thanks to beautiful beef, superb turkey and excellent Timorese poultry, accompanied by vintage Sauternes and Bordeaux, we had a charming dinner.]

The clear implication here is that the French supplied the meat and wine. On this basis it is reasonable to see these seals as the archaeological expression of this single meal. The recovery of these seals in the rubbish dump adjacent to the government house site adds weight to the argument.

The ‘Crown’ Seals (Figure 94-a-h).

This group of eight seals comprises four items inscribed ‘V![]() R’; two seals inscribed ‘W

R’; two seals inscribed ‘W![]() R’; one seal inscribed ‘G

R’; one seal inscribed ‘G![]() R’; 94and one seal inscribed ‘

R’; 94and one seal inscribed ‘![]() D’. These are seen as referring to Queen Victoria, William IV, and George IV, and presumably the bottles to which they were attached were Government issue of some sort. The present insignia of the Department of Defence in Australia, ‘D

D’. These are seen as referring to Queen Victoria, William IV, and George IV, and presumably the bottles to which they were attached were Government issue of some sort. The present insignia of the Department of Defence in Australia, ‘D![]() D’, provides an interesting parallel to the ‘D

D’, provides an interesting parallel to the ‘D![]() ’ seal.

’ seal.

Figure 94. English and Dutch bottle seals from Port Essington: a) VH/S/D (13); b) VSD/8/1 (142); c) V/GEN SUR/Town (34); d) VSD/5/1 (1); e) VH/S/U (23); f) VSD/6/1 (2); g) VSD/4/1 (4); h) VM/11/1 (31); i) VM/6/1 (3).

The ‘AH’ Seal (Figure 94-i)

One seal bearing the initials ‘AH’ can be identified as belonging to A. van Hoboken. A merchant and ship owner of this name lived between 1756 and 1850 and owned a distillery in Delft under the name of van Hoboken en Rogge.

The firm of A. van Hoboken en Zonen had 23 ships in 1842 (W. R. Klein pers. comm.) and the connection between the ‘AH’ seal in the present collection and Hoboken cannot be doubted. I collected a similar seal at Raffles Bay, where the association could be either with the British settlement there, or with a Macassan trepang site in the immediate vicinity, and Campbell Macknight (pers. comm.) has also collected similar seals from a Macassan site. In Darwin I examined three case bottles that had been collected in the Pine Creek area of the Northern Territory. One bore an ‘AH’ seal similar to those collected and mentioned above. The other two bore a similar seal on the shoulder and the moulded inscription on the side ‘A. VAN HOBOKEN ROTTERDAM’. A fourth case bottle, also from Pine Creek, bears the same moulded inscription on the side and a moulded ‘AH’ seal on the shoulder (in the possession of Carmel White, Sydney).

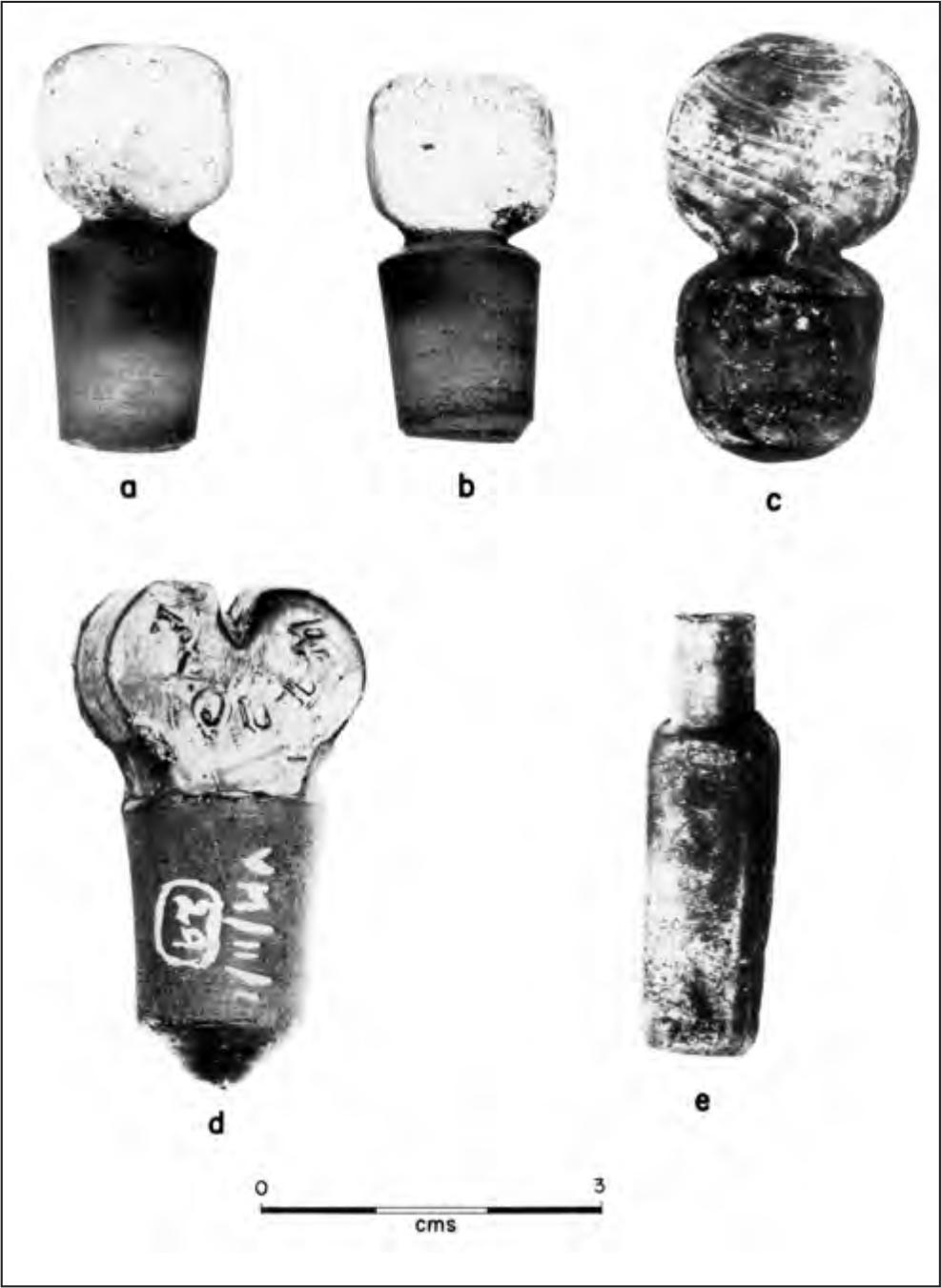

OTHER GLASS ITEMS (Figure 95)

VM/14/1 (38) (Figure 95-e)

Glass phial sometimes referred to as an opium phial, although such a phial might well have contained other things.

VM/S/E (1) (Figure 95-c)

Glass stopper in translucent white glass, oval in cross-section, but this is possibly due to damage by fire.

VQS/7/1 (2) (Figure 95-a)

Circular glass stopper.

VQS/7/1 (29) (Figure 95-b)

Circular glass stopper similar to VQS/7/1 (2), but slightly smaller.

VM/11/1 (29) (Figure 95-d)

Green glass circular stopper, with heart-shaped top. The top has moulded lettering, reading ‘BREVET E’ on one side and ‘E EYQUEM’ on the other. This might translate as ‘patented by Eyquem.’ Château d’Ychem is a Bordeaux region vineyard in the Graves area, renowned for its sauternes, but it is unknown whether it was ever bottled in stoppered bottles. Given its connotations and that it was located at VM with all the Château Margaux seals (see above), and that d’Urville specifically mentioned ‘vin de Sauternes et de Bordeaux’ it seems reasonable to associate this stopper with the French visit. No other information has been obtained that offers closer dating.

Figure 95. Glass stoppers and a small glass phial from Port Essington: a) VQS/7/1 (2); b) VQS/7/1 (29); c) VM/S/E (1); d) VM/11/1 (29); e) VM/14/1 (38).

Sauternes from Château d’Ychem were (and are) as exclusive as Château Margaux. As with the red wines, in 1855 the best sweet Bordeaux wines were classified as Grand Crus Classés in a separate list. Nine wines were classed as Premier Cru, including Château d’Ychem, but it was considered to be so outstanding it alone was accorded the status of Premier Cru 95Supérieur. If this stopper is from a Sauternes bottle, then it can only reasonably be associated with d’Urville’s visit.

Drinking glasses

Lastly, a number of base fragments of wine glasses and tumblers were recovered. Of the wine glass bases two had a diameter of 62 mm and one of 74 mm and were of plain design. The most common form of tumbler appeared to have vertical fluted sides. Unfortunately all the wine glasses and tumblers were very fragmented and some had apparently been flaked by Aborigines, so that no other detailed measurements could be obtained.

DISCUSSION – TYPE B GLASS

The analysis of the bottles from Port Essington has thrown up a number of points of interest. It is clear that the manufacture of moulded bottles in the first half of the nineteenth century in Britain produced bottles which vary from the typical Ricketts bottles, but which were made by a very similar technique. It is not possible so far to illustrate correlations between such things as base diameters and kick heights to differentiate between the last period of free-blown bottles and the early moulded types, but it is suggested that if measurements could be obtained from a large collection of whole examples, patterns of ranges might emerge to enable archaeologists to differentiate base and rim fragments of the two types found in archaeological deposits.

Dating the bottles in the present collection is at best inexact. Just how long bottles stay in circulation is unclear, but from the present collection one whole example, and perhaps many more fragments of free-blown bottles are represented in a site which did not begin until 1838. Thus the terminal date of the manufacture of free-blown bottles may have to be extended beyond the accepted date of 1820. Certainly the free-blown example from Port Essington has a more evolved string-rim than Hume’s example Number 22. Alternatively, the life of any single bottle can be quite long. The evidence of what I have termed ‘Crown’ seals indicates a date of before 1830 for one seal in the collection and a date of before 1837 for two seals. These seals in the present collection (one G![]() R, two W R, four V

R, two W R, four V![]() R) do suggest as archaeological evidence at least a starting date for the settlement which is reasonably close to the historical date. It is of interest that Ruggles-Brise makes almost no mention of this type of seal except to say that the City Museum in Winchester has one seal with a rather crude anchor and the letters G.R. (Ruggles-Brise (1949:51). However, in her lists of seals (1949:137) Ruggles-Brise refers to this seal as ‘G.R. with arrow between the letters’ and also makes reference to a VR seal and a WR seal. Hume (pers. comm.) has also sighted a VR seal from British Columbia.

R) do suggest as archaeological evidence at least a starting date for the settlement which is reasonably close to the historical date. It is of interest that Ruggles-Brise makes almost no mention of this type of seal except to say that the City Museum in Winchester has one seal with a rather crude anchor and the letters G.R. (Ruggles-Brise (1949:51). However, in her lists of seals (1949:137) Ruggles-Brise refers to this seal as ‘G.R. with arrow between the letters’ and also makes reference to a VR seal and a WR seal. Hume (pers. comm.) has also sighted a VR seal from British Columbia.

At first sight, the apparent volume of bottle glass from Port Essington recalled Margaret Kiddle’s (1961) suggestion that drunkenness in early Australia could hardly be overestimated. However, allowing that this collection contains the remnants of 200 bottles and represents perhaps 20% of all the bottle remains in the settlement, and that an average of fifty men were stationed at Port Essington over the eleven years of the settlement, this represents only 0.035 bottles per man per week, or about two bottles per man per year. The best assumption that can be drawn from this evidence is that bottled liquor was either supplementary to casked liquor or irregularly available or restricted to particular groups, such as officers, or combinations of these.

TYPE C GLASS

Table 74 gives the details of the unidentifiable glass in the collection in terms of number and percentage. A further breakdown of this table can be obtained from the individual site reports above. No further analysis was made of the Type C glass. 96